Wholesale Cable Stranding Machine - Steel Wire Armouring Machine for Submarine Cables – LINT TOP

Product Details

Wholesale Cable Stranding Machine - Steel Wire Armouring Machine for Submarine Cables – LINT TOP Detail:

1. Introduction

In recent years, with the rapid development of offshore wind power projects, offshore oil platforms, new island resources and the intercontinental communications, the demand for submarine cables and submarine optical fiber cables has increased day by day. Submarine cables and submarine optical fiber cables play a very important role in the information society and will be an important development direction for the optical fiber cable and electric wire and cable industry in the future.

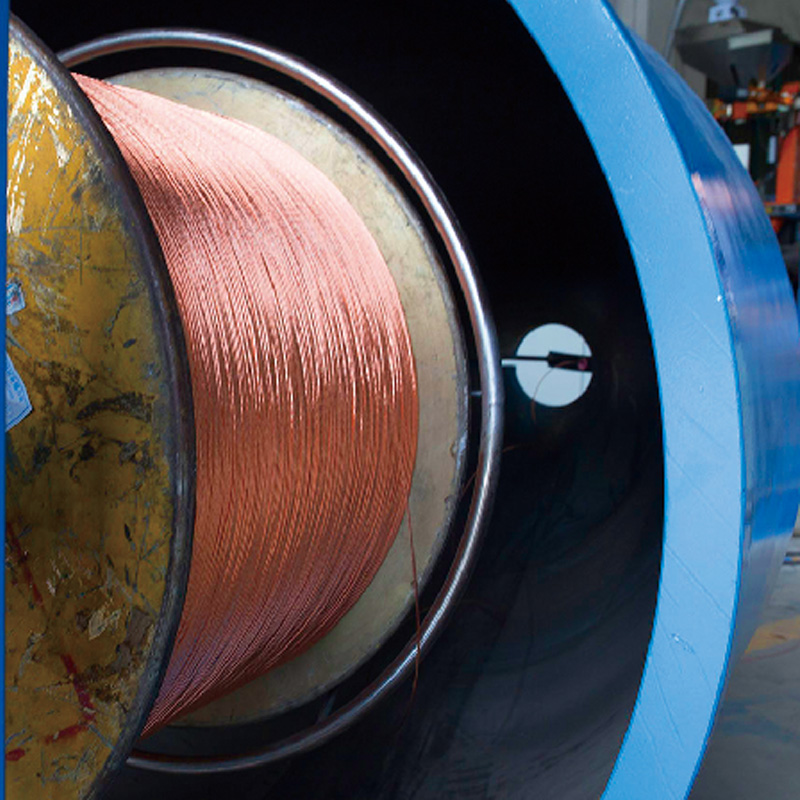

Considering the complicated laying environment and service environment of the ocean, whether it is a submarine cable or a submarine optical fiber cable, it is basically necessary to adopt a structural type of steel wire armor to withstand the external force of the cable and optical cable during the laying and operation process, and protect its complete internal structure.

Steel wire armoring plays a very important role in submarine cables and submarine optical fiber cables. The quality of the armoring layer will directly affect its service life.

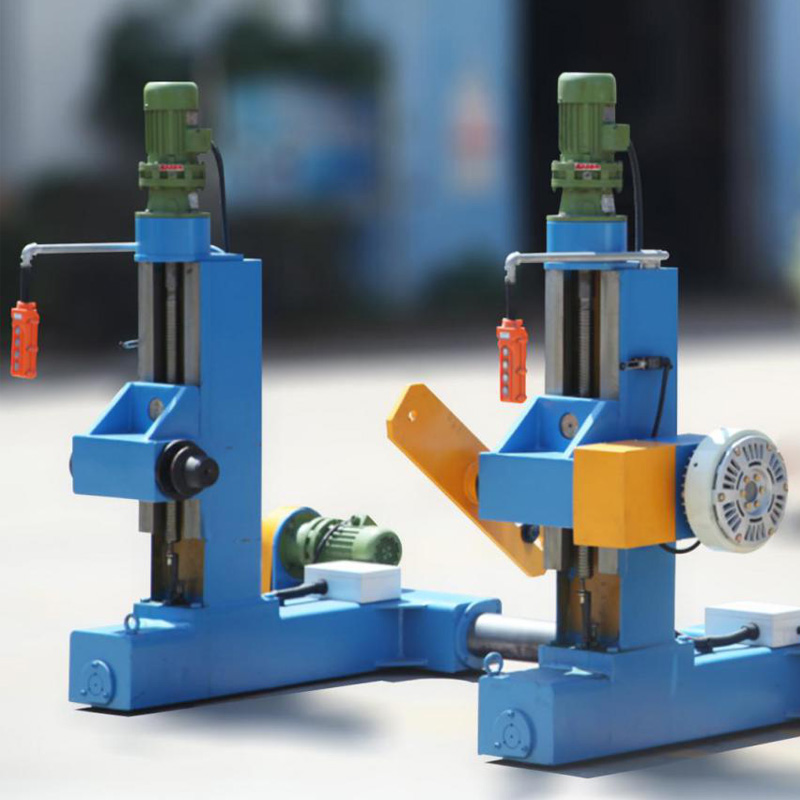

Our company has rich experience in the research & development and manufacturing of submarine cable and submarine optical fiber cable equipment. The steel wire armoring machine developed by our company adopts special structure design which is a cradle-type steel wire armoring machine that can realize 100% backtwist. It can be used for single-layer and double-layer steel wire armoring according to the product structure which is especially suitable for the inner armoring and outer armoring of submarine cables, submarine optical fiber cables and submarine photoelectric composite cables.

The steel wire armoring machine developed by our company is an individual motor type machine.

However, the traditional steel wire armoring machine generally adopts the ground shaft transmission type. This structure has many disadvantages: (1) The ground shaft transmission is an open transmission, with poor lubrication conditions, and dust and other foreign matters are easy to enter to cause the gear wear and damage, and the production site is noisy; (2) Adopting gear transmission with complicated structure, and the gap between the transmission gears is large, which is easy to movement shocks, and damage to the shaft, gears, and casing. At the same time, because of its complicated mechanical structure, the maintenance of the whole machine is more difficult; (3) Due to the limitation of the ground shaft, the speed of the twisting cage is low, and the production speed is difficult to increase, which restricts the production efficiency of armoring; (4) The gearbox has a constant speed ratio, and its pitch can only be changed within a limited range. It cannot be achieved if the pitch required by certain process designs.

2. Features

The individual motor type steel wire armoring machine we developed, each stranding cage and traction are driven by an individual motor with the following characteristics:

(1) Each component of the equipment is driven by an individual motor, with no cabinet, and low operating noise;

(2) Man-machine operation interface, the process parameters can be set and displayed on the operation screen, and can be modified online. Convenient operation improves the production efficiency effectively;

(3) The stranding pitch can be adjusted steplessly with wide pitch range, which is convenient for improving the production process;

(4) Adopting the planetary gear train structure, which can realize 100% full backtwist armoring.

3. Main Technical Parameters

The main technical parameters of the equipment are as follows:

|

Structural type |

φ630/12+12 |

φ630/18+18 |

|

Pay-off bobbin(mm) |

φ630 |

φ630 |

|

Steel wire diameter (mm) |

Φ2.0~Φ6.0 |

Φ2.0~Φ6.0 |

|

Max. twisting speed of cage (rpm) |

60 |

40 |

|

Twisting pitch |

Stepless |

|

|

Operating direction |

According to customers’ requirements |

|

| Note: In addition to the above types in the table, we can also provide other types of steel wire armoring machine according to customers’ product structure. | ||

Compared with the traditional ground shaft transmission type steel wire armoring machine, the individual motor type steel wire armoring machine abandons the multi-stage gearbox and the ground shaft transmission system, simplifies the complex mechanical structure of the whole machine, reduces the difficulty of mechanical maintenance and reduces the noise of production site. With wide range of pitch variation, which can realize the stepless adjustment of the pitch, facilitate the improvement of the production process, and meet the different requirements of the steel wire armoring process products.

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, have confidence in the very first and management the advanced" for Wholesale Cable Stranding Machine - Steel Wire Armouring Machine for Submarine Cables – LINT TOP , The product will supply to all over the world, such as: Korea, Costa Rica, Naples, We have many years' experience in hair product production, and our strict QC Team and skilled workers will ensure that we give you top hair products with the best hair quality and workmanship. You will get successful business if you choose to cooperate with such a professional manufacturer. Welcome your order cooperation!

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.