Well-designed Cable Coiling And Packing Machine - Planetary Strander – LINT TOP

Product Details

Well-designed Cable Coiling And Packing Machine - Planetary Strander – LINT TOP Detail:

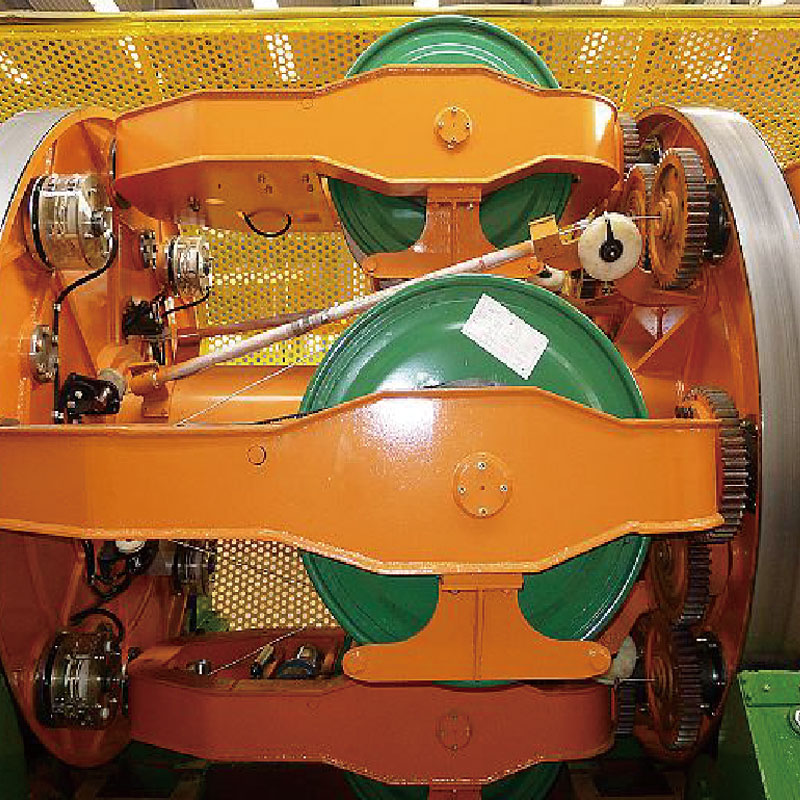

Planetary strander is an important equipment for wire and cable stranding. It is mainly used for copper stranded wire, aluminum stranded wire, steel stranded wire, steel core aluminum stranded wire, and cabling of insulated wire core and OPGW stranding, etc.

Generally, the traditional planetary strander adopts the ground shaft transmission type, and the transmission of capstan and the stranding cage are usually driven by the same motor through the reduction box, gearbox, ground shaft, angle box, etc. The traversing line is controlled individually or adopts centralized transmission and controlled by the above motors.

This structure has many disadvantages:

(1) The ground shaft transmission is an open transmission with poor lubrication conditions and foreign objects such as dust are easy to enter will cause gear wear and damage and loud noise at the work site.

(2) Adopting gear shifting, the gearbox structure is complex, and the gap between the shifting gears is large, which is prone to motion shock and damage the ground shaft, gears, box, etc. At the same time, because of its complicated mechanical structure, it makes the maintenance and repair of the whole machine more difficult.

(3) Restricted by the ground shaft, the speed of the twisting cage is low, and the production speed is difficult to increase, which restricts the production efficiency of the twisted wire production.

(4) Due to the fixed speed ratio of the gearbox, its pitch can only be changed within a limited range, and it is impossible to achieve the pitch required for certain process designs.

The cradle stranding machine developed by our company integrates the stranding production process of domestic first-class cable manufacturers, adopts the sub-motor transmission mode, and each winch and traction are driven by separate motors.

1. Features

1. Each parts of this equipment is driven by independent motor with low noise and without cage.

2. Human-machine interface, you can set, display and adjust the parameters on touch screen. Easy operation improves the production efficiency.

3. The stranding pitch can realize the stpeless adjustment and large pitch range is easy to improve the production technology.

4. Adopting planetary gear structure, can realize 100% back-twisting.

2. Main Technical Parameters

|

Bobbin size (mm) |

Max. Rotation speed (rpm) |

Single wire (mm) |

||||||||||||

|

With roller |

Without roller |

|||||||||||||

|

6B |

8B |

12B |

16B |

18B |

24B |

6B |

12B |

18B |

24B |

Aluminum wire |

Copper wire |

Aluminum clad steel |

Optical fiber unit |

|

|

φ400 |

126 |

112 |

98 |

86 |

155 |

140 |

122 |

108 |

1.5~4.0 |

1.2~4.0 |

1.2~3.5 |

2.5~4.0 |

||

|

φ500 |

105 |

93 |

82 |

71 |

136 |

123 |

110 |

97 |

1.5~5.0 |

1.3~5.0 |

1.3~3.5 |

3.0~5.0 |

||

|

φ630 |

85 |

80 |

74 |

70 |

65 |

57 |

110 |

96 |

84 |

74 |

1.8~6.0 |

1.5~6.0 |

1.5~4.5 |

3.0~6.0 |

Compared with the traditional ground shaft-driven cradle stranding machine, the multi-stage gearbox and ground shaft transmission system are abandoned, which simplifies the complex mechanical structure of the whole machine, reduces the difficulty of mechanical maintenance and reduces the noise on the production site. The pitch variation range is wide, and the stepless adjustment of the pitch can be realized, which is convenient for improving the production process and can meet the process requirements of different stranded products.

Product detail pictures:

Related Product Guide:

Using a full scientific good quality administration system, very good quality and superior faith, we win good standing and occupied this discipline for Well-designed Cable Coiling And Packing Machine - Planetary Strander – LINT TOP , The product will supply to all over the world, such as: Belgium, Frankfurt, Slovenia, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. We also offer agency service---that act as the agent in china for our customers. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.