Top Suppliers Power Cable Test Termination - AC Resonance PD Free Test System – LINT TOP

Product Details

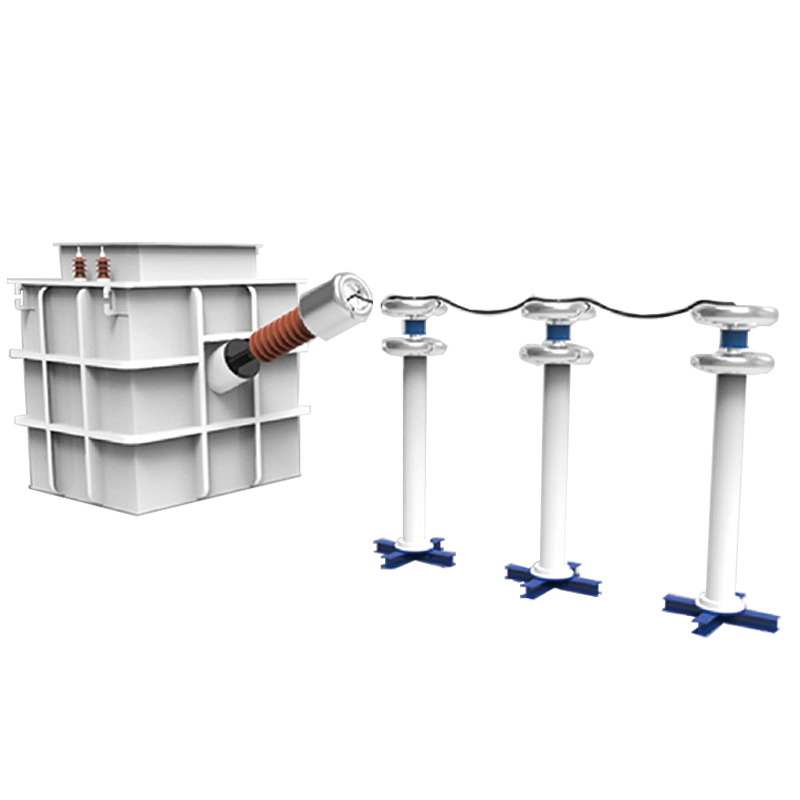

Top Suppliers Power Cable Test Termination - AC Resonance PD Free Test System – LINT TOP Detail:

Compared with overhead lines, cable lines have the advantages of concealed laying, less climate interference, less maintenance, and less impact on the city's city appearance, and their application in urban power grids is becoming more and more common. Among them, cross-linked polyethylene (XLPE) power cables have become mainstream cables because of their good electrical mechanical performance, large transmission capacity, and flexible construction and installation. Long-distance high-voltage XLPE cables have been widely used in urban construction.

In order to ensure the safe operation of the line, the handover acceptance test must be carried out before the power cable is put into operation, so as to avoid the loss of operation failure caused by mechanical damage, installation process defects and other problems. The basic design of the AC resonance non-partial discharge test system provided by our company is the specific characteristics of the energy storage of the capacitive test object.

1. Introduction

AC series resonance PD free test system is mainly used in power industry, power transformer, HV PT, HV switchgear, ect. This system application conforms to XLPE cable power frequency voltage test and PD test requirement, and is suitable for PD test, voltage test and PD fault location test for XLPE cables before leaving factory. The test item includes AC voltage test, PD test,and cable long duration test.

2. Environment

• Maximum altitude: ≤ 1000 m

• Altitude 100 m increase voltage rate lowered by 1%

• Ambient Temperature for HV component operation: 3 ~ 45℃

• HV component relative humidity (non-condensing): ≤ 95 %

• Temperature for electronic control and measuring:

+10 ~ +45℃

• Relative Humidity of electronic components: ≤ 80%

• Transport temprature: 20℃~ + 60℃

• Anti-seismic: 8 grade

• Grounding resistance: ≤ 1.0Ω

• No dust

3. Main Technical Parameters

• Rated voltage: 100kV ~ 1500kV (and above)

• Rated energy: 300kVA ~ 30000kVA (and above)

• Noise: ≤ 75dB (2 meters away from equipment)

• Q value: Q ≥ 20 ~ 100

• PD: 80% voltage PD ≤ 2pC

• Load: Under rated capacity, 1 hour on, 1 hour off,3 ~ 6 times per day; under 50% capacity,continuous operation. (customer can require longer operation)

4. Features

(1) Bigger reactor power (ineffective power) output with very low actual power input;

(2) After output filtered, output waveform distortion ratio is 0.5% lowered than total resonance wave distortion;

(3) When tested object fault happens, fault current generated in power loop will be deleted, and the fault point damage is the lowest;

(4) The operation mode is controllable resonance status, so accidental resonance will not happen, while this happens to traditional power

frequency test transformer when doing capacitive load test.

(5) The complete application can significantly save costs.

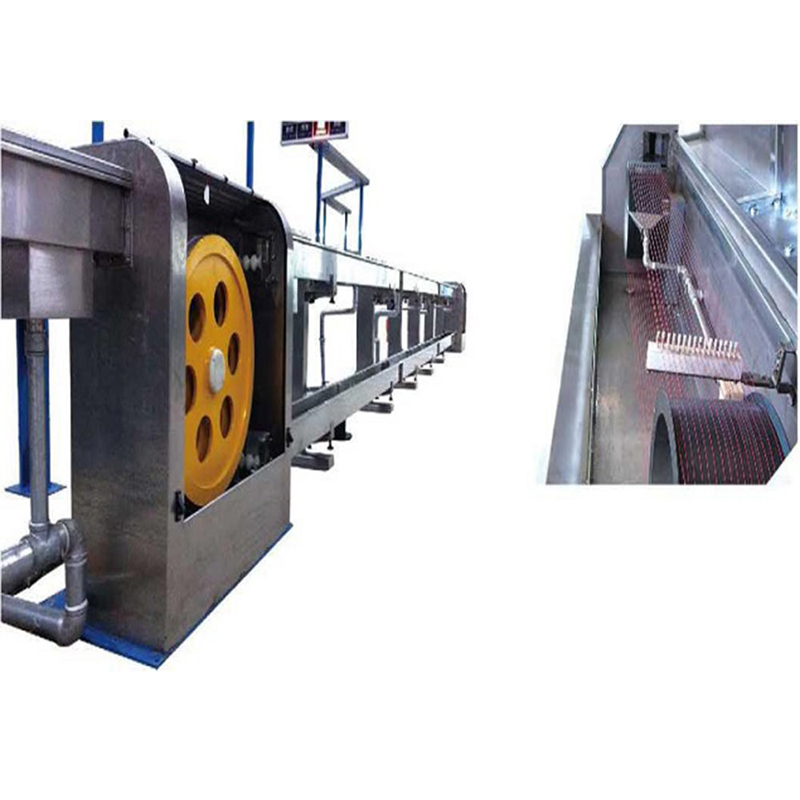

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, belief the very first and management the advanced" for Top Suppliers Power Cable Test Termination - AC Resonance PD Free Test System – LINT TOP , The product will supply to all over the world, such as: European, Turin, Hanover, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our goods. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you personally always.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.