Quality Inspection for Copper Rod Breakdown Machine - Optical Cable Secondary Coating Line – LINT TOP

Product Details

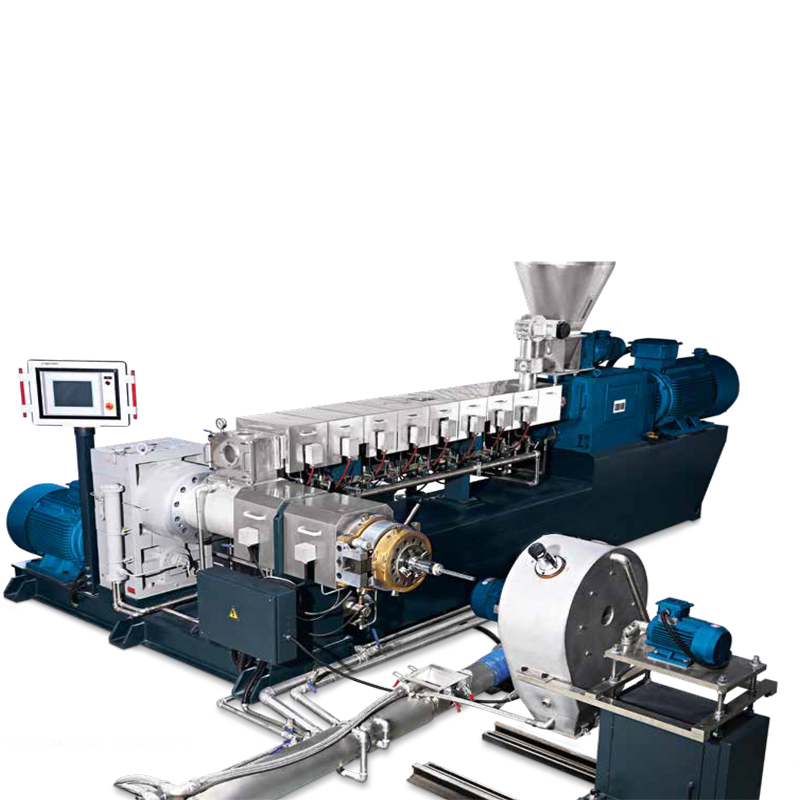

Quality Inspection for Copper Rod Breakdown Machine - Optical Cable Secondary Coating Line – LINT TOP Detail:

1. Introduction

The secondary coating of optical fiber is to coat the outer surface of the optical fiber once, and then squeeze the loose tube with a certain diameter and a certain thickness. The primary coated fiber can move freely in the loose tube, and the loose tube is filled with water blocking ointment.

The secondary coating of the optical fiber is the second layer of protection for the optical fiber after the primary coating and coloring. The optical strength of the optical fiber after one-time coating is still low, and it cannot be used without further reinforcement. The purpose of the secondary coating operation is to protect the primary coating of the optical fiber, increase the mechanical strength of the optical fiber, and improve the transmission characteristics and temperature characteristics of the optical fiber.

This is one of the most important processes in the manufacture of optical cables, and its quality directly affects the performance indicators of finished optical cables.

We have many years of experience in research and development and manufacture of optical fiber and cable production equipment. The optical cable secondary coating line provided by us can be used to extrude 2-12 cores grease filled fiber optic loose tube, suitable for extruding PBT material. The extruded shape is round, uniform in diameter and smooth.

The whole line adopts the control technology (PC + PLC mode) which combines industrial control computer and programmable logic controller.

As the main control system, PLC realizes the linkage control of the whole line. The operator can select the stop, slow, and fast running states through the interface. The production line will automatically switch between the three states according to the operating instructions and the various state signals of the equipment. There is no sudden change in the speed-up and speed-down time. It can automatically respond to various fault signals and have clear fault indications. The production speed and metering data are clearly displayed, and the meter length can be pre-designed.

The industrial computer realizes human-machine data exchange and production data recording. The man-machine interface provided by IPC includes production interface, curve interface, and recipe interface. The human-computer interaction interface is friendly and easy to operate.

2. Main Technical Parameters

|

Model |

LT06 |

|

Number of fiber cores |

2~12 |

|

Payoff tension(N) |

(0.4~1.5)±0.05 |

|

Payoff bobbin(mm) |

φ236~φ305 |

|

Structure speed(m/min) |

≤800 |

|

Production speed(m/min) |

20~600(φ1.8mm) |

|

Surplus length control |

0~3‰ |

|

Takeup bobbin(mm) |

PN800 |

|

Additional loss(dB/km) |

≤0.02 |

|

Outer diameter of beam tube(mm) |

1.2~4.0 |

Product detail pictures:

Related Product Guide:

Just about every member from our large efficiency income crew values customers' wants and enterprise communication for Quality Inspection for Copper Rod Breakdown Machine - Optical Cable Secondary Coating Line – LINT TOP , The product will supply to all over the world, such as: Mecca, Bogota, Libya, Due to the changing trends in this field, we involve ourselves into products trade with dedicated efforts and managerial excellence. We maintain timely delivery schedules, innovative designs, quality and transparency for our customers. Our moto is to deliver quality products within stipulated time.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.