Planetary Strander

Product Details

Planetary strander is an important equipment for wire and cable stranding. It is mainly used for copper stranded wire, aluminum stranded wire, steel stranded wire, steel core aluminum stranded wire, and cabling of insulated wire core and OPGW stranding, etc.

Generally, the traditional planetary strander adopts the ground shaft transmission type, and the transmission of capstan and the stranding cage are usually driven by the same motor through the reduction box, gearbox, ground shaft, angle box, etc. The traversing line is controlled individually or adopts centralized transmission and controlled by the above motors.

This structure has many disadvantages:

(1) The ground shaft transmission is an open transmission with poor lubrication conditions and foreign objects such as dust are easy to enter will cause gear wear and damage and loud noise at the work site.

(2) Adopting gear shifting, the gearbox structure is complex, and the gap between the shifting gears is large, which is prone to motion shock and damage the ground shaft, gears, box, etc. At the same time, because of its complicated mechanical structure, it makes the maintenance and repair of the whole machine more difficult.

(3) Restricted by the ground shaft, the speed of the twisting cage is low, and the production speed is difficult to increase, which restricts the production efficiency of the twisted wire production.

(4) Due to the fixed speed ratio of the gearbox, its pitch can only be changed within a limited range, and it is impossible to achieve the pitch required for certain process designs.

The cradle stranding machine developed by our company integrates the stranding production process of domestic first-class cable manufacturers, adopts the sub-motor transmission mode, and each winch and traction are driven by separate motors.

1. Features

1. Each parts of this equipment is driven by independent motor with low noise and without cage.

2. Human-machine interface, you can set, display and adjust the parameters on touch screen. Easy operation improves the production efficiency.

3. The stranding pitch can realize the stpeless adjustment and large pitch range is easy to improve the production technology.

4. Adopting planetary gear structure, can realize 100% back-twisting.

2. Main Technical Parameters

|

Model |

Max. rotating speed (rpm) |

Single wire diameter (mm) |

||||||

|

6B |

12B |

18B |

24B |

Copper wire |

Aluminum wire |

Aluminum clad steel wire |

Stainless steel fiber optic loose tube |

|

|

630 |

85 |

72 |

62 |

52 |

1.8-4.6 |

1.8-5.0 |

1.2-4.5 |

1.5-5.0 |

Compared with the traditional ground shaft-driven cradle stranding machine, the multi-stage gearbox and ground shaft transmission system are abandoned, which simplifies the complex mechanical structure of the whole machine, reduces the difficulty of mechanical maintenance and reduces the noise on the production site. The pitch variation range is wide, and the stepless adjustment of the pitch can be realized, which is convenient for improving the production process and can meet the process requirements of different stranded products.

Main Components

This equipment is composed of column type or portal type pay-off, stranding cage, die holder, taping equipment (optional), meter counter, dual-capstan, portal or column type take-up, safety rails, loading system, electrical control system and so on.

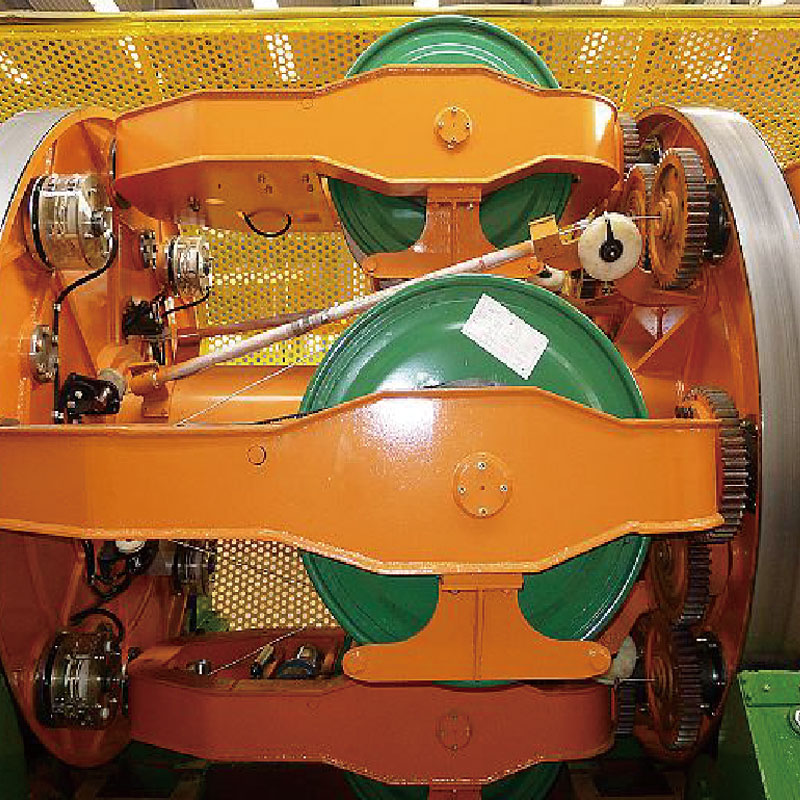

1. Stranding Cage

Every stranding cage is driven by independent AC variable frequency motor has the function of left-right rotating. The whole stranding cage has good rigidity and balance during working. Except the center pay-off bobbin, other bobbins are set in the stranding cage. It can strand two or three layers of single wires. More stranding single wires one time improves the production efficiency.

The number of each cage can be minimum to 6 bobbins and maximum to 36 bobbins. The minimum diameter of bobbin can be 250mm and maximum diameter can be 800 mm. The circumference of bobbins can be divided into 3, 4, 6 and other equal parts structure.

Planetary type back-twisting structure is set behind every stranding cage, and 100% back-twisting is achieved by this structure. If the stranding product does not need back-twisting, you can also abandon this step. Easy switch between back-twisting and non back-twisting.

The wire rack in the cage has various forms of tension control methods: hysteresis tension, mechanical tension, mechanical belt feedback tension, active pay-off, etc. The tension can be adjusted to ensure that the tension of the core wire released on each cradle is stable and balanced. When using active pay-off, the actual tension of each pay-off is displayed on the main console and can be set. The electric control system is provided with a tension correction adjustment proportional coefficient, so that the actual tension is consistent with the displayed tension.

Adopting end-shaft clamping wire reel, with mechanical safety locking mechanism. The clamping mechanism can be operated manually or with pneumatic tools. The upper and lower reels are convenient, fast, reliable and safe.

The twisted cage is equipped with a broken wire protection device to realize broken wire parking protection.

Adopting butterfly-shaped pneumatic brake device. The brake cylinder controls the tension of the wire disc to ensure that the pressure cylinder acts on the tension disc evenly, and the tension control is more accurate.

2. Single-line Preforming Device

This device has three discs which are equipped with pre-twisted guide wheels. The pre-twisted guide wheels on the first and third discs are fixed, the first and second discs can be moved back and forth, and the middle disc The pre-twisted guide wheel can move up and down. The device can be deformed according to the Z direction or S direction required by the stranding process, and the required shape is pre-twisted in advance to eliminate the internal stress of the strand, so that the single wire will not rebound or loose during the stranding process.

3. Bobbin Hanger

Each cage is equipped with loading plate which adopts single-bobbin way with easy loading bobbin and has feature of safety.

Installation and Commissioning

After the order is established, we will provide customers with foundation drawing, pipe drawing and layout drawing. Customers can build and lay foundations according to the drawings we sent.

We will make a detailed commissioning plan with our customers before the equipment arrives at the factory. Customers need to prepare materials for installation and commissioning. Of course we will send a detailed preparation list to help.

We will send two experienced engineers, including a mechanical engineer and an electrical engineer to guide the installation, and start the equipment with no-load test and load test. Engineers will try best to train the workers be familiar with the equipment.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.