OEM/ODM Factory Cable Testing Machine - Impulse Voltage Test System – LINT TOP

Product Details

OEM/ODM Factory Cable Testing Machine - Impulse Voltage Test System – LINT TOP Detail:

1. Introduction

In the development of a modern society, the development of various fields has increased the demand for power. In order to ensure the stability of the power system, it is necessary to increase the emphasis on high-voltage power cable management and choose its test methods and tests reasonably. Technology to find problems in power cables in time. Using reasonable test methods and detection techniques can improve the efficiency and quality of the power sector, reduce energy consumption and waste, and enhance the stability of the power system.

The most common reason for the failure of high-voltage power cables is their own unqualified quality, which will cause huge safety hazards during their operation.

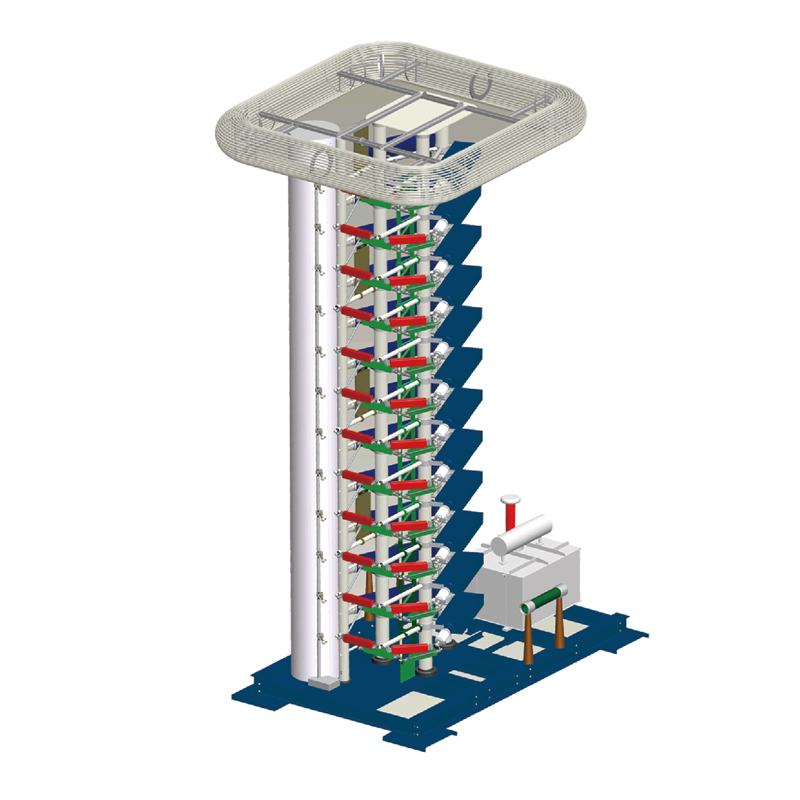

The impulse voltage test system is a test device for high-voltage power products such as power transformers, high-voltage transformers, high-voltage switches, and power cables. Carrying out voltage tests on high-voltage power products can produce standard lightning waves, operating waves, and cut-off waves. It is an essential test instrument for detecting high-voltage power products.

2. Environment

• Maximum altitude: 1000 m

• Altitude increases 100m, and rated voltage lowers 1%

• Operation temperature for HV component: +10 ~ +45℃

• HV component relative humidity (non-condensing) ≤ 95 %

• Temperature for electronic control & measuring: +10 ~ +45℃

• Relative Humidity of electronic components: ≤ 80%

• Components storing and transport temperature: 20 ~ + 60℃

• Anti-seismic: Grade 8

• Grounding resistance: < 0.3Ω

• No dust

3. Main Technical Parameters

• Rated voltage: ±100kV ~ 6000kV (and above)

• Rated energy: 2.5kJ ~ 600kJ

• Rated charging voltage: ±100kV ±200kV

•Stage capacitance: 1.0µF/200kV 2.0µF/100kV(According to total capacitance)

• Standard lightening impulse: 1.2/50µS efficiency: 85 ~ 90% (1.2±30%/50±20%uS )

• Switch impulse: 250/2500µS efficiency: 65 ~ 70% (250±20%/2500±60%uS )

4. Features

(1) Large in voltage utilization coefficient;

(2) Convenient in wave adjustment, simple in operation, excellent in synchronization performance and reliable in motion;

(3) An automatic control technique is adopted in the constant-current charge, which is high automation and strong anti-interference capacity;

(4) A digital measurement and analysis system for the impulse test date are adopted, which increase the technical level and the efficiency of the impulse voltage tests;

(5) High Automaticity;

(6) Optical communication, strong anti interference ability;

(7) Large energy, wide application range.

Product detail pictures:

Related Product Guide:

Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for OEM/ODM Factory Cable Testing Machine - Impulse Voltage Test System – LINT TOP , The product will supply to all over the world, such as: Cyprus, Las Vegas, Guatemala, Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal goods. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. Detailed data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're going to allow you to get complete acknowledge about our items and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

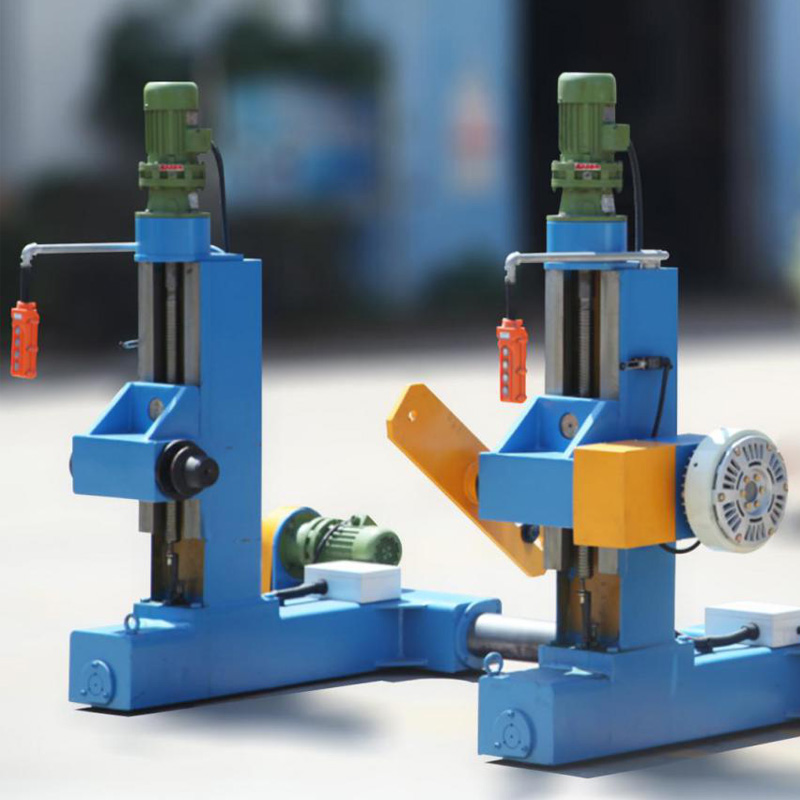

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

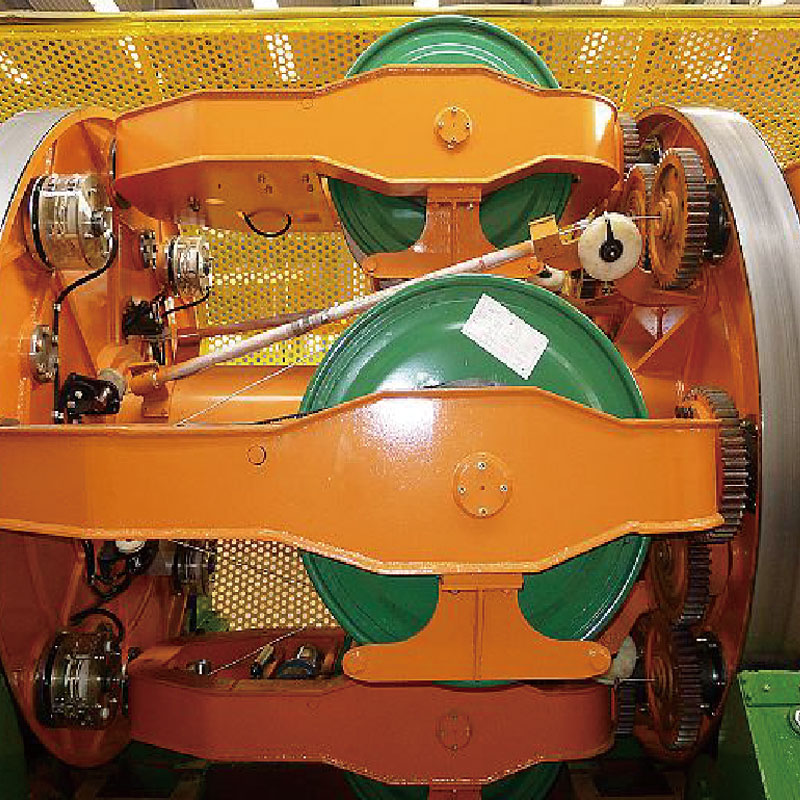

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.