OEM/ODM Factory Cable Testing Machine - HV Shielded Test Room – LINT TOP

Product Details

OEM/ODM Factory Cable Testing Machine - HV Shielded Test Room – LINT TOP Detail:

1. Introduction

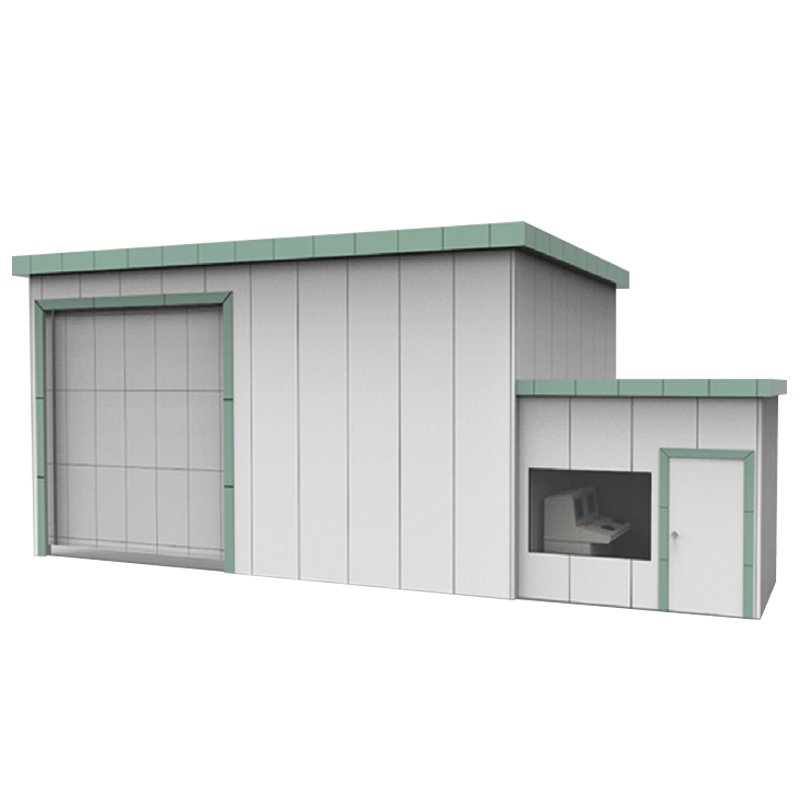

The HV partial discharge hall is mainly used for power transformer, HV inductor, arrester, HV switch, HV XLPE cable and so on, the shielded room is used for avoiding electromagnetic interference which can affect partial discharge test.

2. Technical Parameters

|

Rated Voltage (kV) |

±100-2000 (and above) |

|

Exterior Dimension (m) |

60*40*30(L*W*H)(bigger size is available) |

|

Grounding Resistor |

Requirement<1.0Ω |

|

Insulating Resistance |

≤10KΩ(measured after completing shielding room, insulating ground mainly used fro HV cable partial discharge hall, because there is a high requirement for partial discharge of HV cable with large capacity) |

|

Partial Discharge |

≤2.0 PC(Shielding hall partial discharge value is below 2 PC if equipment can reach below 2.0PC) |

|

Magnetic Field |

10kHZ attenuation 60dB linearity rise to 100KHZ, attenuation 100dB |

|

Electric Field |

From 1kHZ to 100kHZ attenuation 100dB |

Product detail pictures:

Related Product Guide:

We insist on offering high-quality creation with superior business enterprise concept, honest revenue plus the greatest and fast service. it will bring you not only the high quality solution and huge profit, but essentially the most significant is usually to occupy the endless market for OEM/ODM Factory Cable Testing Machine - HV Shielded Test Room – LINT TOP , The product will supply to all over the world, such as: Rotterdam, Austria, Bolivia, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.