OEM Manufacturer Automatic Wire Coiling Machine - High Speed Double Twist Buncher – LINT TOP

Product Details

OEM Manufacturer Automatic Wire Coiling Machine - High Speed Double Twist Buncher – LINT TOP Detail:

During the production of wires and cables, multi-strand conductors need to be twisted before the insulation extrusion.The stranding of multi-strand conductors can be carried out by stranding machine or bunching machine. When the diameter of single wire is very small and the stranding finished wires with extra-soft performance, then you can only use the twisting machine instead of traditional stranding equipment.

Wires from a number of single-wire pay-off bobbins which are layered and arranged on the fixed stand will enter into the main engine through the dividing plate.

The single wire is twisted by the rotation of rotating body to complete the twist stranding of conductors.

The twist buncher provided by us can be used for stranding bare copper, tin-plated copper, silver-plated copper, copper-clad aluminum wire, special alloy wire, insulated core wire.

Our twist buncher machine can not only carry on the bunch stranding of the multi-strand conductors, but also can carry on regular stranding by replacing stranding with bunching.

It can replace (1+6) tubular stranding machine and (1+6) rigid frame strander. Compared with the tubular stranding machine, the double twist buncher machine has 2 ~ 4 times capacity than it.

1. Equipment Features

(1). With variable frequency speed regulation way and touch screen control,convenient and efficient for operation

(2). The magnetic powder clutch controls the winding tension, the PLC automatically track winding line adjust tension , and the winding tension is constant without fluctuation.

(3). Using the electromagnetic brake to brake, internal and external wire break, various fault automatic brake.

2. Main Technical Parameters

|

Model |

Max. rotation (rpm) |

Inlet diameter (mm) |

Stranded section (mm2) |

Max stranded outer diameter (mm) |

|

LT630 |

2000 |

0.18~0.68 |

0.18~6 |

3.2 |

|

LT800 |

1200 |

0.68~1.70 |

2.5~10 (Rigid structure) |

6.5 |

|

2.5~16 (Flexible structure) |

||||

|

LT1000 |

1000 |

0.68~2.13 |

4.0~16 (Rigid structure) |

9.0 |

|

4.0~25 (Flexible structure) |

||||

|

LT1250 |

500 |

0.87~2.52 |

4~35 (Rigid structure) |

20.0 |

|

6~50 (Flexible structure) |

3. Bunching Effect

Our high speed double twist bunchers can meet bunched requirements of different specification.It has the characteristics of high speed, high efficiency, light weight, small floor area, low noise and high quality bunched product.

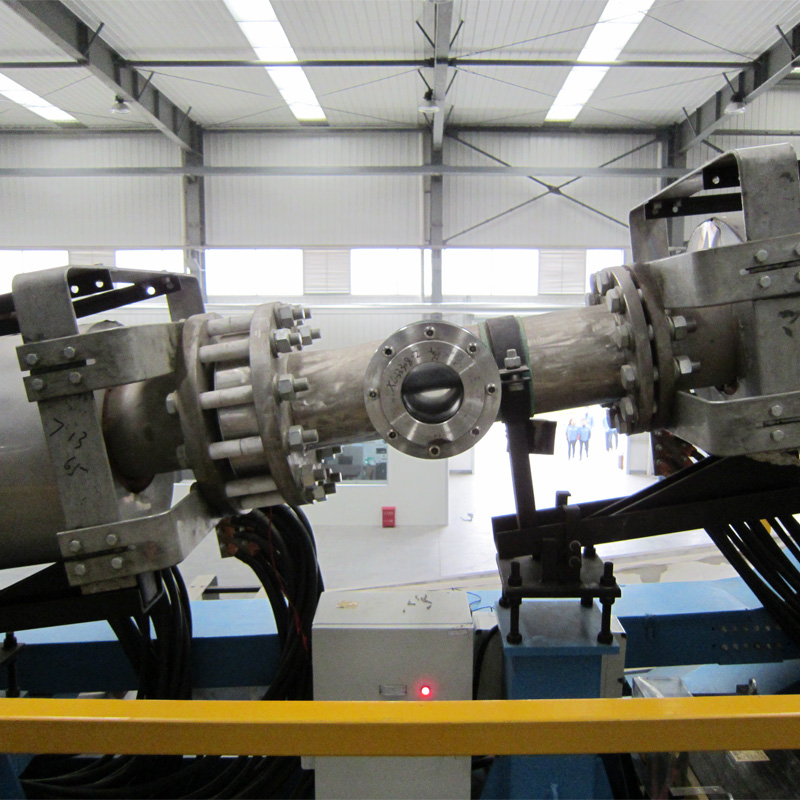

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as theory of "quality the basic, have faith in the initial and administration the advanced" for OEM Manufacturer Automatic Wire Coiling Machine - High Speed Double Twist Buncher – LINT TOP , The product will supply to all over the world, such as: Paraguay, Rio de Janeiro, Pretoria, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.