New Fashion Design for Cable Laying-Up Line - Continuous Extrusion Production Lines for Copper Flat Wires – LINT TOP

Product Details

New Fashion Design for Cable Laying-Up Line - Continuous Extrusion Production Lines for Copper Flat Wires – LINT TOP Detail:

1. Introduction

For the production of copper flat wire, round wire, commutator segment and other solid copper conductor.

2. Features

1. Much low loss of raw material, which makes high utilization materials.

2. With specially designed extrusion wheel, chamber and dies, our extrusion lines have longer service life and higher output compared with others’ same mode machine, which also brings a lower power consumption and lower production cost.

3. Adopting position sensor in the swing dancer, which ensures the speed synchronization of take-up and the extrusion machine by a loop-back circuit.

4. Adopting SIEMENS S7-1200 PLC controller, ABB DCS550 DC Driver and all major low power components of ABB™ Electricity, which ensure the reliability of control system.

3. Technical Parameters

|

Model |

LT-250T |

LT-300T |

LT-300AT |

|

Wheel Dia. (mm) |

250 |

300 |

300 |

|

Feedstock Material |

Copper and Copper Alloy(Brass) |

||

|

Max. Width of Flat Wire (mm) |

15 |

50 |

50 |

|

Min. Dia. of Round Wire (mm) |

Φ1.8 |

Φ2.6 |

Φ3.6 |

|

Product Section Area (mm²) |

2.5-50 |

5-250 |

10-250 |

|

Average Output (kg/h) |

160(110) |

480(330) |

620(430) |

Notes: We also have other models for aluminum flat wires, copper busbar and copper profile, etc. Please contact our sales for more information.

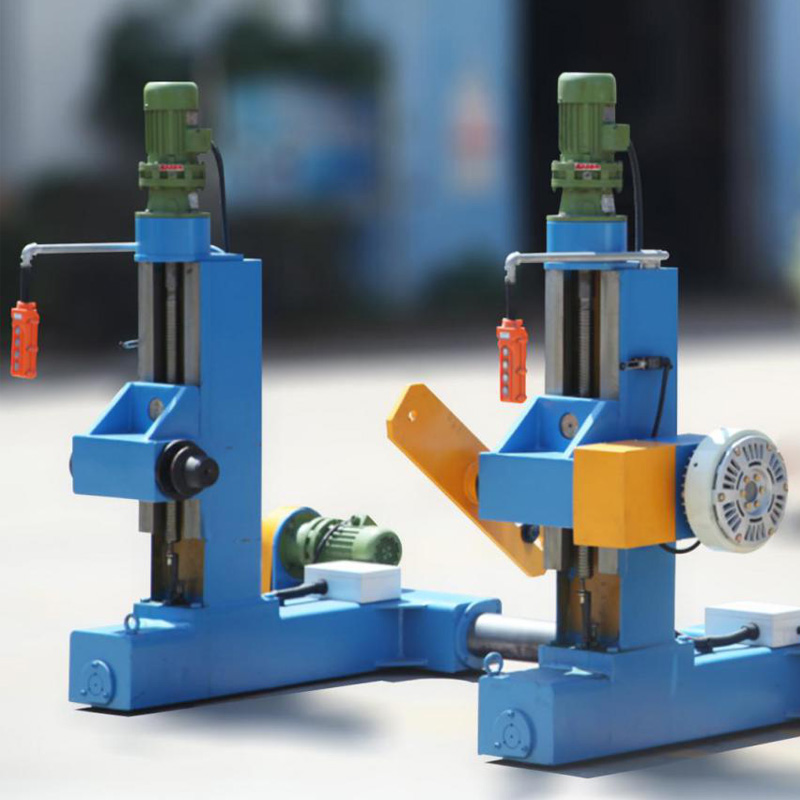

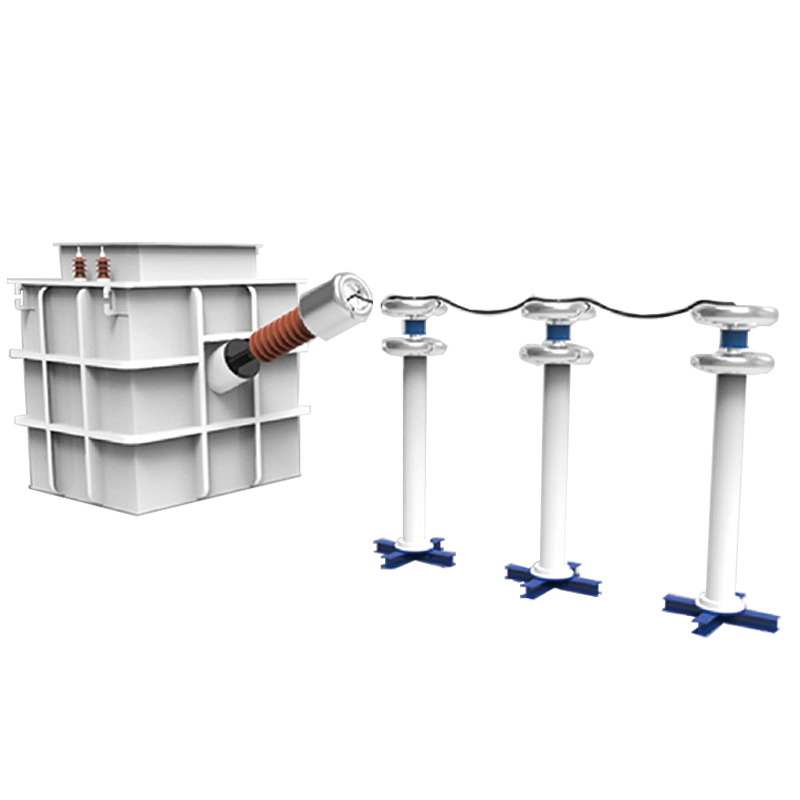

Product detail pictures:

Related Product Guide:

We now have many fantastic staff members customers superior at advertising, QC, and working with varieties of troublesome problem within the generation system for New Fashion Design for Cable Laying-Up Line - Continuous Extrusion Production Lines for Copper Flat Wires – LINT TOP , The product will supply to all over the world, such as: Madagascar, Singapore, Armenia, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for yourself in China. Of course, other services, like consulting, can be offered too.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.