Manufacturer of Drum Type Stranding Machine - Skip Type Strander / Bow Twister – LINT TOP

Product Details

Manufacturer of Drum Type Stranding Machine - Skip Type Strander / Bow Twister – LINT TOP Detail:

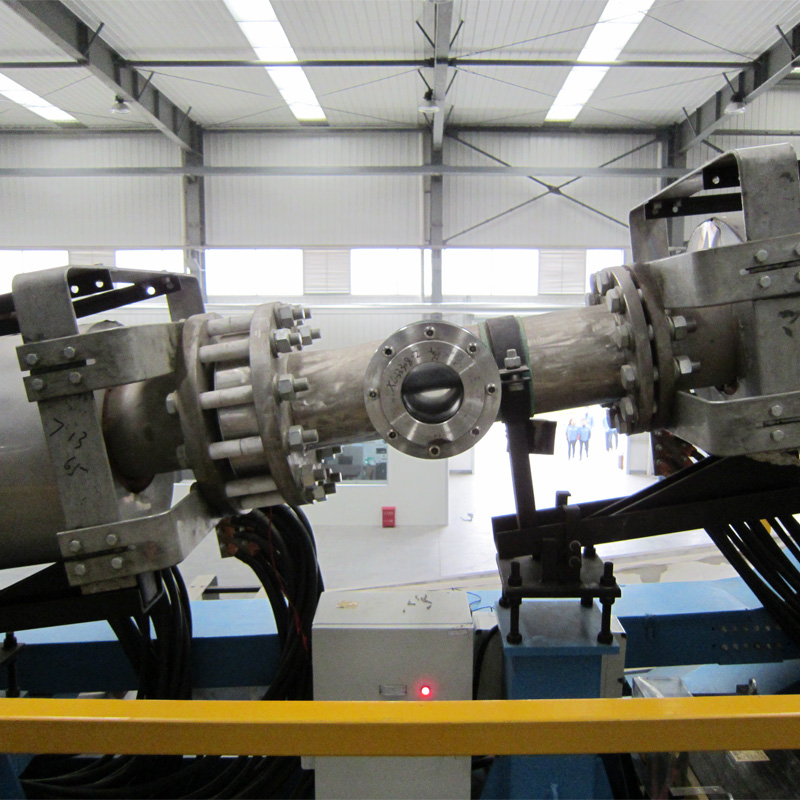

Bow twister is the important equipment for wire and cable cabling, it is mainly used for control cables, low voltage cables, rubber sheathed cables, mining cables, overhead insulated cables and other products.

With the continuous decrease of wire and cable products’ profit, it is imperative to reduce the production cost for the manufacturers. And improving production efficiency is one of the effective ways to reduce production cost. With the unique structure, the production efficiency of bow twister is more than twice as much as the tubular stranding, and more than five times of cage stranding machine. Due to the advantages of high production efficiency, bow twister has been used more and more widely.

Our company has many years of experience in research and development of bow twister, integrates with the cabling production process of China first-class cable manufacturers fully. We can provide 630, 800, 1000, 1250, and 1600 types of bow twister. And we can provide 1+3, 1+4, 1+5, 1+6 various types of cabling according to customers’ needs, which effectively broaden the production range of product, and can meet the cabling up to 7 core cables. It is the best equipment for mass, continuous and efficient cabling.

1. Equipment Features

1.The twisting bow is made of imported carbon fiber and glass fiber composite material with high strength, light weight, low noise during rotation.

2. Small moment of inertia and high speed.

3. Simple structure, convenient operation and maintenance.

4. 100% back twist can be achieved.

2. Main Technical Parameters

|

Bobbin size (mm) |

Max. rotating speed (rpm) |

Single wire Dia. (mm) |

||||

|

3B |

4B |

5B |

6B |

Soft structure conductor |

Hard structure conductor |

|

|

φ630 |

880 |

850 |

830 |

800 |

φ5~φ10 |

φ1.5~φ4.0 |

|

φ800 |

680 |

650 |

620 |

600 |

φ5~φ10 |

φ2.0~φ5.0 |

|

φ1000 |

430 |

400 |

370 |

350 |

φ8~φ15 |

φ3.0~φ6.0 |

|

φ1250 |

330 |

300 |

270 |

250 |

φ8~φ15 |

φ3.0~φ6.0 |

|

φ1600 |

250 |

220 |

200 |

180 |

φ10~φ20 |

φ3.5~φ8.0 |

Product detail pictures:

Related Product Guide:

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for Manufacturer of Drum Type Stranding Machine - Skip Type Strander / Bow Twister – LINT TOP , The product will supply to all over the world, such as: Cambodia, Nigeria, Korea, Now we have a dedicated and aggressive sales team, and many branches, catering to our main customers. We have been looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.