Factory wholesale Wire Braiding Machine - Triple-layer Co-extrusion Dry-cure CCV Line – LINT TOP

Product Details

Factory wholesale Wire Braiding Machine - Triple-layer Co-extrusion Dry-cure CCV Line – LINT TOP Detail:

1. Introduction

This Continuous Catenary Vulcanization (CCV) Line is designed for continuous producing 6-35KV, 35-132KV XLPE insulated power cable with 3-layer co-extrusion.

2. Features

1. Controlled by computer and operated by touch screen, communicates with profibus.

2. Adopting 65 conductor shield, 150 insulation, 90 insulation shield, triple-layer co-extrusion.

3. Controlled by field density, shifting phase trigger function of tubes.

4. The specially designed triple-layer co-extrusion crosshead ensures the joint speed raising not eccentric after modulating with low speed and can make finished cable after 30-40m.

5. The man-machine communicate menu can save the technological parameter for using at any moment.

6. Sag control. The working principle is of contactless type with the features of narrow band emission, strong signal, weak signal receiving and high anti-interference ability, widely uses DC speed governing and AC frequency conversion control.

3. Technical Parameters

|

Voltage Class |

XLPE: 6-35KV |

XLPE: 10-110KV |

XLPE: 35-220KV |

|

Conductor |

Copper: 35-630mm2 |

Copper: 25-800mm2 |

Copper: 150-2000mm2 |

|

Aluminum: 50-800mm2 |

Aluminum:35-1000mm2 |

Aluminum:150-2000mm2 |

|

|

Max. Cable Weight (kg/m) |

10 |

12.5 |

34 |

|

Max. Dia. (mm) |

70 |

80 |

119 |

|

Tube Layout |

Half-catenary |

Half-catenary |

U type |

|

Installed Capacity (KVA) |

750-930 |

1050 |

1000 |

|

Line Speed (m/min) |

0-30 |

0-25 |

0.2-8 |

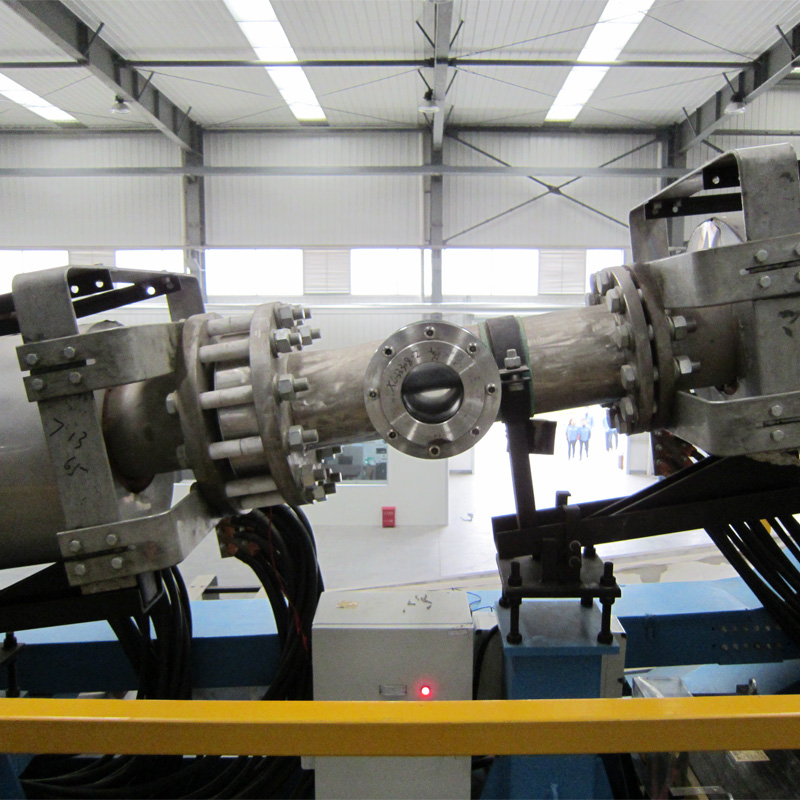

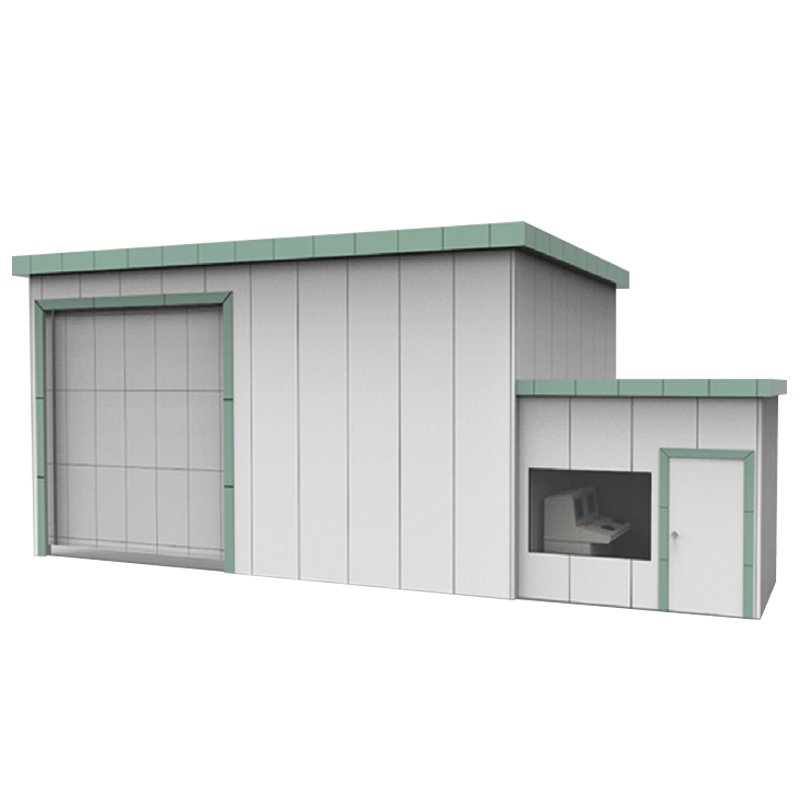

Product detail pictures:

Related Product Guide:

The key to our success is "Good Products Good quality, Reasonable Value and Efficient Service" for Factory wholesale Wire Braiding Machine - Triple-layer Co-extrusion Dry-cure CCV Line – LINT TOP , The product will supply to all over the world, such as: Peru, Rome, France, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we offer, effective and satisfying consultation service is supplied by our specialist after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So please make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We are confident that we are going to share mutual achievement and create strong co-operation relations with our companions in this marketplace. We're searching forward for your inquiries.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.