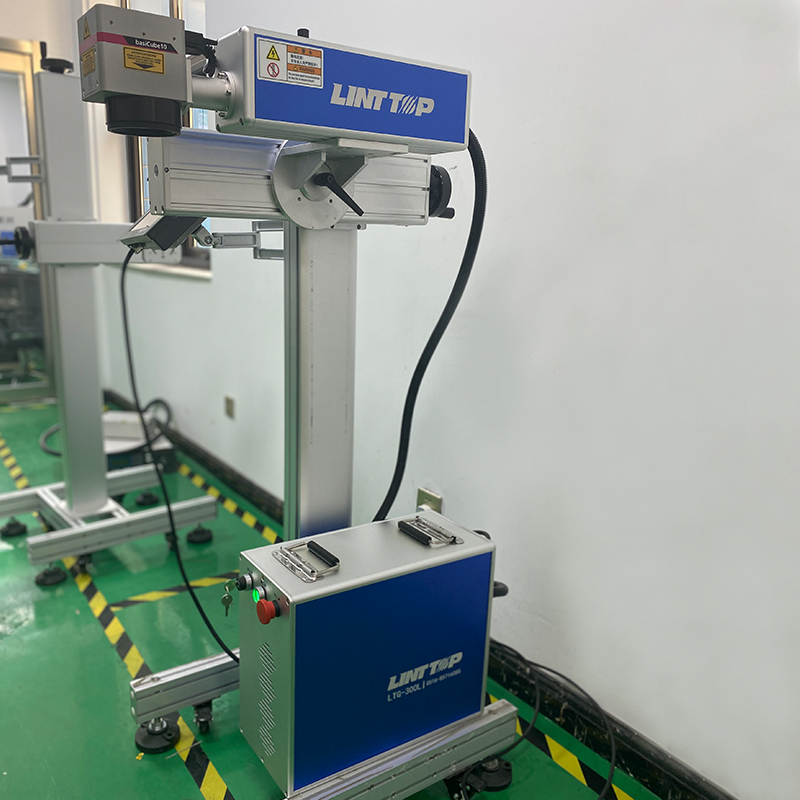

Factory Free sample Cable Making Machine - Drum Twister – LINT TOP

Product Details

Factory Free sample Cable Making Machine - Drum Twister – LINT TOP Detail:

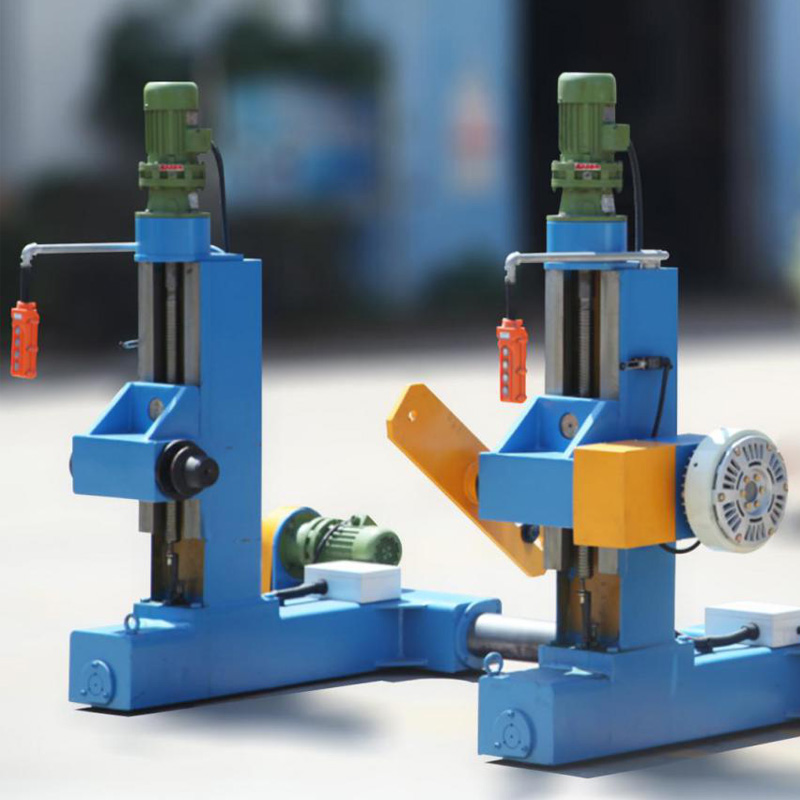

Drum twister is an important device for stranding wires and cables which is mainly used for stranding large-length and large-section power cables and milliken conductors. It can also be armored with steel wire or steel tape, or shielded with copper wire or copper tape.

This is currently a relatively advanced twisting equipment with high production efficiency, the speed is generally above 30m / min. The pay-off bobbins can be rotated synchronously with the take-up frame, or can be fixed without turning to realize back twist or non back twist. The take-up bobbin can simultaneously complete the double movement of twisting and take-up. The size of the take-up bobbin can reach up to 4000mm, which improves the production efficiency and expands the production range compared with ordinary stranding equipment.

We have many years of experience in the development of the drum twister, the rotary caterpillar type drum twister we developed combines the production technology of domestic first-class cable manufacturers. We can provide 2000, 2500, 3150, 3500, 4000, 4200 and other types of drum twisters which can achieve 3 cores , 4 cores, 5 cores, "4 + 1" cores and "3 + 2" cores structures, effectively expanding the production range.

1. Equipment Features

The drum twister from us adopts sub-motor driving mode, with the following features:

1. The main components of the equipment have high precision, good balance of rotation, high strength, high speed and high production efficiency.

2. Technical parameters can be set, displayed on the touch screen, and can be modified online. The PLC can calculate various operating data under the process to ensure the accurate realization of the process. The type and location of the fault can also be displayed on the touch screen to quickly identify the fault point and reduce maintenance time.

3. The equipment can be configured with metal and non-metal wrapping devices, steel wire armoring devices, filling and longitudinal wrapping devices according to customer requirements to meet different process requirements.

2. Main Technical Parameters

|

Bobbin size (mm) |

Max. rotating speed (rpm) |

Single wire dia. (mm) |

Max load (t) |

|||

|

Take-up |

Payoff |

Fork-type |

Cradle-type |

Take-up |

Pay-off |

|

|

Φ2000 |

Φ1250 |

80 |

100 |

Φ100 |

10 |

3 |

|

Φ2500 |

Φ1600 |

60 |

70 |

Φ100 |

12 |

5 |

|

Φ3150 |

Φ2000 |

40 |

50 |

Φ120 |

20 |

10 |

|

Φ3500 |

Φ2500 |

30 |

40 |

Φ120 |

25 |

12 |

|

Φ4000 |

Φ2500 |

25 |

30 |

Φ130 |

30 |

12 |

|

Φ4200 |

Φ2500 |

25 |

30 |

Φ130 |

30 |

12 |

The drum twister is driven by individual motors, with advanced design, reasonable structure, beautiful appearance, convenient operation, good process performance, high reliability, low failure rate and convenient maintenance,etc.

Product detail pictures:

Related Product Guide:

We've one of the most innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for Factory Free sample Cable Making Machine - Drum Twister – LINT TOP , The product will supply to all over the world, such as: Sevilla, United Arab Emirates, Porto, Based on products and solutions with high quality, competitive price, and our full range service, we have accumulated experienced strength and experience, and we've built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality items and passionate service. Let's open a new chapter of mutual benefit and double win.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.