Excellent quality High Speed Braiding Machine - FTTH Drop Cable Extrusion Line – LINT TOP

Product Details

Excellent quality High Speed Braiding Machine - FTTH Drop Cable Extrusion Line – LINT TOP Detail:

1. Introduction

Butterfly-type drop optical cable is a new type of indoor fiber optic cable. It is suitable for indoor and terminal installation places that are often need to be bent. It can be cut according to the distance of the site when wiring, and it can be installed with quick connection connectors and optical fiber cold connectors. There is no need to melt fiber during site construction, which greatly improves engineering construction efficiency.

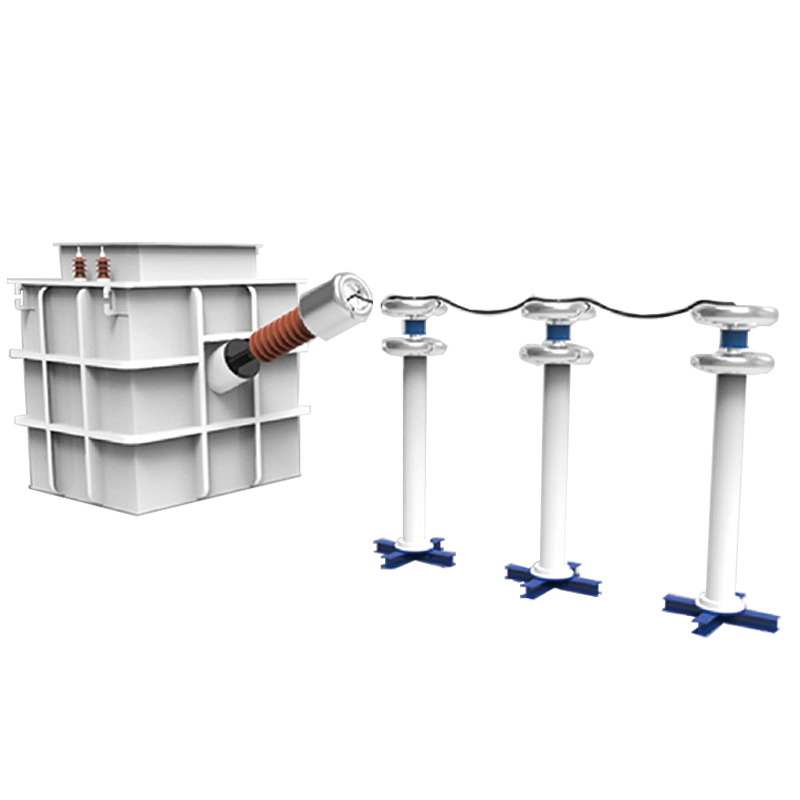

The structure of the butterfly-type drop optical cable is to place the optical fiber between two parallel reinforcements and then extrude a layer of plastic sheath.

The structure of the self-supporting butterfly-type optical fiber cable is to add a metal hanging wire to the structure of the common butterfly-type optical fiber cable. The structure is as follows:

The significant technical feature of the FTTH butterfly-introduced optical cable is not only to provide greater bandwidth, but also to enhance the network's transparency of data formats, rates, wavelengths and protocols, relax requirements on environmental conditions and power supply, and simplify maintenance and installation. Therefore, this kind of optical cable has been widely used in optical communication systems and has good development prospects.

The significant technical feature of the FTTH butterfly-introduced optical cable is not only to provide greater bandwidth, but also to enhance the network's transparency of data formats, rates, wavelengths and protocols, relax requirements on environmental conditions and power supply, and simplify maintenance and installation. Therefore, this kind of optical cable has been widely used in optical communication systems and has good development prospects.

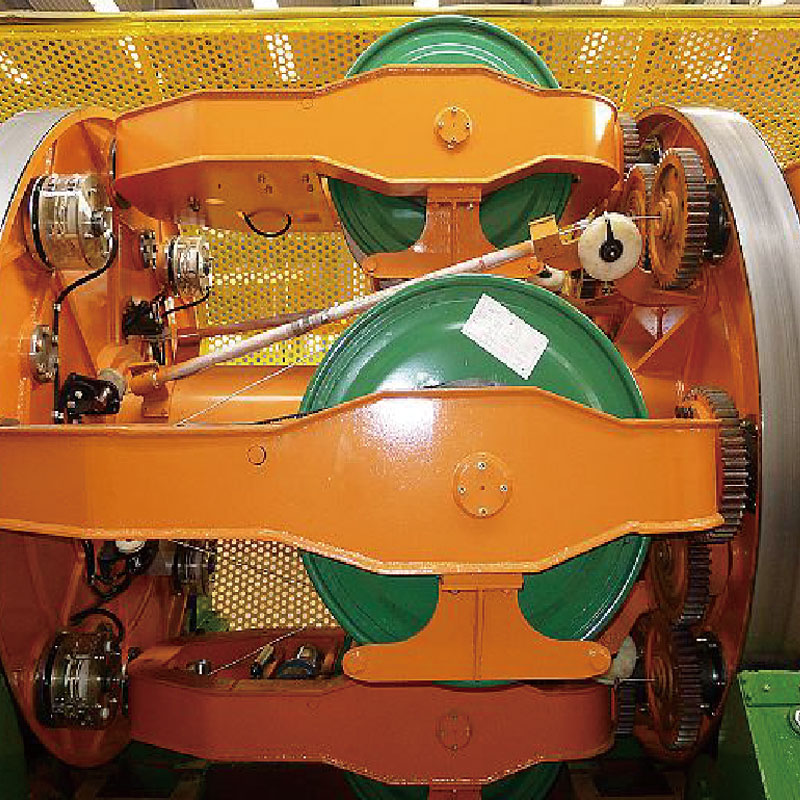

The introduction of FTTH butterfly cables requires special production equipment. Our company has many years of experience in research and development and manufacturing of optical fiber and cable production equipment. The FTTH butterfly-introduced optical cable production line provided is suitable for the production of (1-2) core butterfly-introduced optical cables. It can be extruded with PVC, LSZH and other jacket materials. The production line has the characteristics of uniform extrusion outer diameter, smooth appearance, fast production speed, high production efficiency, precise take-up and pay-off tension, and easy operation of the production line. It is a professional production equipment for FTTH butterfly-shaped optical cable.

The whole machine of the production line adopts the control technology combining industrial computer and programmable logic controller, namely (PC + PLC) method to realize the synchronous operation of the whole line and the independent operation of the single machine; the operation of the production line, the setting of the parameters and the display are all passed Industrial control computer to carry out, the production control process such as motor start, stop, signal given, motor speed and other production status acquisition are realized by PLC; data transmission between industrial control computer and PLC through communication port; production operation, alarm display can be realized , Emergency stop of production line and other functions.

2. Main Technical Parameters

|

Extruding material |

PVC、LSZH |

|

Structure speed (m/min) |

200m/min |

|

Production speed (m/min) |

Max.160m/min(2.0mm×3.0mm, LSZH) Max.150m/min (2.0mm×5.0mm, LSZH) |

|

The pay-off tension of optical fiber (N) |

(0.4N~1.5N)±0.05N |

|

Pay-off reel size for optical fiber |

25km,50km International common optical fiber reel |

|

Pay-off reel size for FRP |

PN400 |

|

Pay-off reel size for steel wire |

PN630, PN800 |

|

Take-up size |

PN630, PN800 |

|

Fiber optic additional loss |

≤0.02dB/km |

Product detail pictures:

Related Product Guide:

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for Excellent quality High Speed Braiding Machine - FTTH Drop Cable Extrusion Line – LINT TOP , The product will supply to all over the world, such as: Uzbekistan, Jordan, Sudan, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.