China Gold Supplier for Rbd Machine With Individual Drivers - Upward Continuous Casting System for Oxygen-free Copper Rod – LINT TOP

Product Details

China Gold Supplier for Rbd Machine With Individual Drivers - Upward Continuous Casting System for Oxygen-free Copper Rod – LINT TOP Detail:

1. Introduction

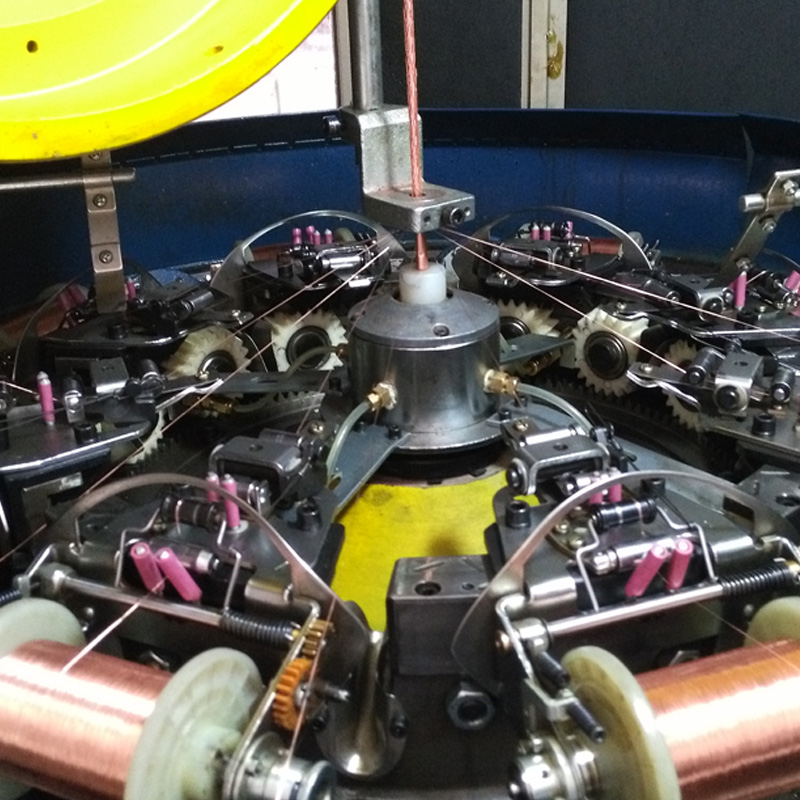

Upward continuous casting machine is a new technology to produce oxygen free copper rod, tube, and flat billet at a great length. Its production of oxygen free copper rod and profiles are featured with high conductivity and low oxygen content. Compare with some traditional technology, this new method is lower in capital investment, easy to operate, economic in producing consuming, high quality in production, and flexible in changing production size but no pollution to environment.

2. Usage

Rod: For cable, wire, magnet wire, enameled wire, telephone lines, computer lines and so on.

The copper alloy wire: Car, high-speed tram wires.

3. Technical Parameters

|

Model |

Numbers of Casting Head |

Rod Dia. (mm) |

Annual Output(t) |

Installed Capacity (Kva) |

Electricity Consumption (kw) |

|

LT-04-Q2-S-B-8/20 |

4 |

8-20 |

2000 |

330 |

≤360 |

|

LT-06-Q2-S-B-8/20 |

6 |

8-20 |

3000 |

330 |

≤350 |

|

LT-06-Q2-S-A-16/30 |

6 |

16-30 |

3000 |

330 |

≤350 |

|

LT08-QL-S-B-8/20 |

8 |

8-20 |

4000 |

480 |

≤340 |

|

LT10-QL-S-A-16/30 |

10 |

16-30 |

6000 |

480 |

≤340 |

|

LT10-QL-S-B-8/20 |

10 |

8-20 |

5000 |

480 |

≤340 |

|

LT12-QL-S-B-8/20 |

12 |

8-20 |

6000 |

480 |

≤340 |

|

LT14-QG-S-A-16/30 |

12 |

16-30 |

8000 |

750 |

≤340 |

|

LT16-QR-S-A-16/30 |

16 |

16-30 |

10000 |

950 |

≤330 |

|

LT16-QG-S-B-8/20 |

16 |

8-20 |

8000 |

750 |

≤330 |

|

LT20-QW-S-B-8/20 |

20 |

8-20 |

10000 |

950 |

≤320 |

|

LT20-QW2-S-A-16/30 |

20 |

16-30 |

12000 |

1000 |

≤320 |

|

LT24-QW2-S-B-8/20 |

24 |

8-20 |

12000 |

1000 |

≤320 |

|

LT24-QW3-S-A-16/30 |

24 |

16-30 |

15000 |

1100 |

≤320 |

|

LT28-QW3-S-B-8/20 |

28 |

8-20 |

15000 |

1100 |

≤320 |

Product detail pictures:

Related Product Guide:

Our solutions are widely regarded and trustworthy by consumers and may meet continually modifying financial and social requirements for China Gold Supplier for Rbd Machine With Individual Drivers - Upward Continuous Casting System for Oxygen-free Copper Rod – LINT TOP , The product will supply to all over the world, such as: Hungary, Puerto Rico, Paraguay, Our professional engineering group will always be ready to serve you for consultation and feedback. We're able to also offer you with absolutely free samples to meet your requirements. Finest efforts will likely be produced to offer you the ideal service and goods. For anyone who is thinking about our company and merchandise, be sure to contact us by sending us emails or contact us quickly. As a way to know our merchandise and firm. lot more, you can come to our factory to find out it. We'll always welcome guests from all over the world to our business to build company relations with us. Be sure to feel free to get in touch with us for business and we believe we've been intending to share the top trading practical experience with all our merchants.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.