China Buy Wire Marker Machine Suppliers - Copper Wire Recycling Machine – LINT TOP

- 1. Prospect and Development Trend

- 2. Main Technical Parameters

- 3. Features

- 4. Workflow

- 5. Processing Effect

Product Details

China Buy Wire Marker Machine Suppliers - Copper Wire Recycling Machine – LINT TOP Detail:

1. Prospect and Development Trend

With the development of modern communication and industry, the demand for metal wires is increasing.Due to the rapid replacement of old and new products, the amount of waste wire and cable recycling is increasing year by year.The traditional method is to burn the wire and cable with its own package to recover the metal in the wire and cable.This method is harmful to the environment, and it is not processed accurately by any equipment.The products of cable skin combustion can asphyxiate people and seriously damage the lungs and kill people.

The cost of copper, aluminum, iron and various rare and precious metals and plastics in the cable is much lower than the cost of obtaining resources directly from ore, raw materials and other smelting processes, and energy saving.These waste cable recycling, formed a veritable recycling economy.This recycling mode highlights the efficient use of resources and the pursuit of maximum economic and social benefits with the least resource consumption and environmental cost.

The copper rice machine provided by our company is specialized in processing all kinds of cables at different levels including communication cables and various miscellaneous cables which are not suitable for processing by wire stripping machine.

After disassembling the scrap copper miscellaneous wire, the copper rice machine separates the metal and plastic rubber sheet of the scrap wire and then blows the air to directly obtain the high-purity copper rice.Plastic can be sent to a plastic factory for recycling and other plastic products.The rice is sent to smelters for direct smelting and casting.Among them, purple hybrid copper can be continuously cast and rolled to produce low-oxygen bright copper rod, or electrolysate to produce high-purity electrolytic copper powder with high conductivity and thermal conductivity, as the raw material for the production of self-lubricating bearings and electronic components.

2. Main Technical Parameters

| Model | LT200 | LT300 | LT400 | LT500 | LT600 | LT800 | LT1000 |

| Size | 2500mmx1800mmx2000mm | 2600mmx1600mmx2300mm | 4800mmx2200mmx2700mm | 5500mmx2250mmx2850mm | 6100mmx3200mmx2600mm | 10000mmx7000mmx3000mm | 10000mmx7000mmx2800mm |

| Total power | 18kW | 24kW | 45kW | 48kW | 55kW | 90kW | 105kW |

| Main power | 7.5kW | / | / | 30kW | 37kW | 45kW | 55kW |

| Blowing power | 2.2kW | / | / | 4kW | 4kW | 4kW | 4kW*2 |

| Suction power | 4kW | / | / | 4kW | 4kW | 4kW | 4kW*2 |

| Shaker power | 2.2kW | / | / | 2.2kW | 2.2kW | 2.2kW | 2.2kW*2 |

| Vibrating screen power | 0.12kW*4 | / | / | 0.12kW*4 | 0.12kW*4 | 0.12kW*4 | 0.12kW*4*2 |

| Weight | 1500Kg | 1.4T | 3.5T | 3.6T | 3.6T | 6.5T | 10T |

| Power consumption | 16kW/h | 15kW/h | 28kW/h | 25kW/h | 35kW/h | 55kW/h | 70kW/h |

| Power supply | 380Ⅴ,50HZ | 380Ⅴ,50HZ | 380Ⅴ,50HZ | 380Ⅴ,50Hz | 380Ⅴ,50Hz | 380Ⅴ,50Hz | 380Ⅴ,50Hz |

| Production capacity | 80-100Kg/h | 100kg/h | 200-300kg/h | 300-400kg/h | 300-500kg/h | 600-900kg/h | 700-1000kg/h |

Note: All the equipment is suitable for wire dia within 80mm, and when the dia beyond 80mm, the peeling machine is needed.

3. Features

1. PLC program control, uniform feeding and automatic alarm device, guarantee the maximum stability of the equipment running.

2. Compact structure, beautiful appearance, reasonable layout, safe and reliable.

3. The crusher, separator equipment and integrated equipment use platform type combination, which it’s convenient for move and transport, adding the flexibility of the whole line.

4. Crusher rotor adopts alternating shaft, making higher production efficiency, lower noise, and more stable operation.

5. The sorting efficiency of high-precision air flow separator is as high as 95%-99%.

6. Feedback system leads the semi-finished products to second grinder, improving the sorting efficiency.

7. Pulse dust catcher is effective in suppressing dust spillover, and the efficiency of dust removal is up to 99%.

8. Air filtration system can effectively avoid the dust produced by the second grinder.

9. Hydraulic system can open the second grinder body easily, and it’s easy for staff to do daily maintenance.

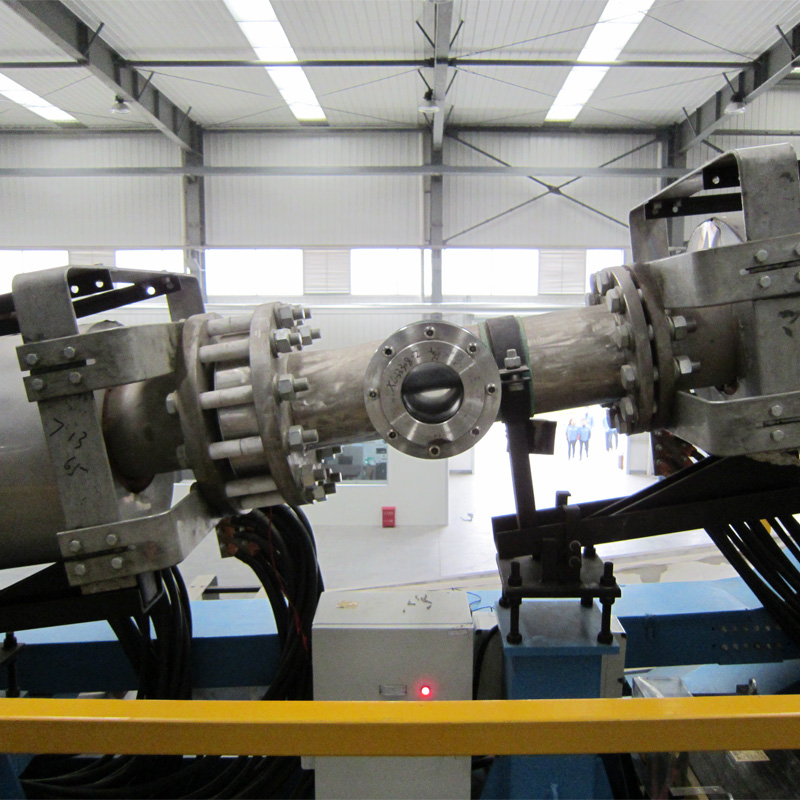

4. Workflow

Belt Conveyor → Shaft Shredder → Magnetic Separator → Belt Conveyor → Feeder → Belt Conveyor → Crusher → Vibration Separation+Dust Removal → Static Separation / Fine Wires Vibrating Screen + Dust Removing Device

5. Processing Effect

Product detail pictures:

Related Product Guide:

We're convinced that with joint endeavours, the business between us will bring us mutual benefits. We are able to guarantee you products high quality and competitive value for China Buy Wire Marker Machine Suppliers - Copper Wire Recycling Machine – LINT TOP , The product will supply to all over the world, such as: Mozambique, Auckland, Slovenia, With strong technical strength and advanced production equipment, and SMS people purposefully , qualified, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.