China Buy Wire Granulator Machine Factories - Robotic Welding Machine – LINT TOP

Product Details

China Buy Wire Granulator Machine Factories - Robotic Welding Machine – LINT TOP Detail:

1. Production Introduction

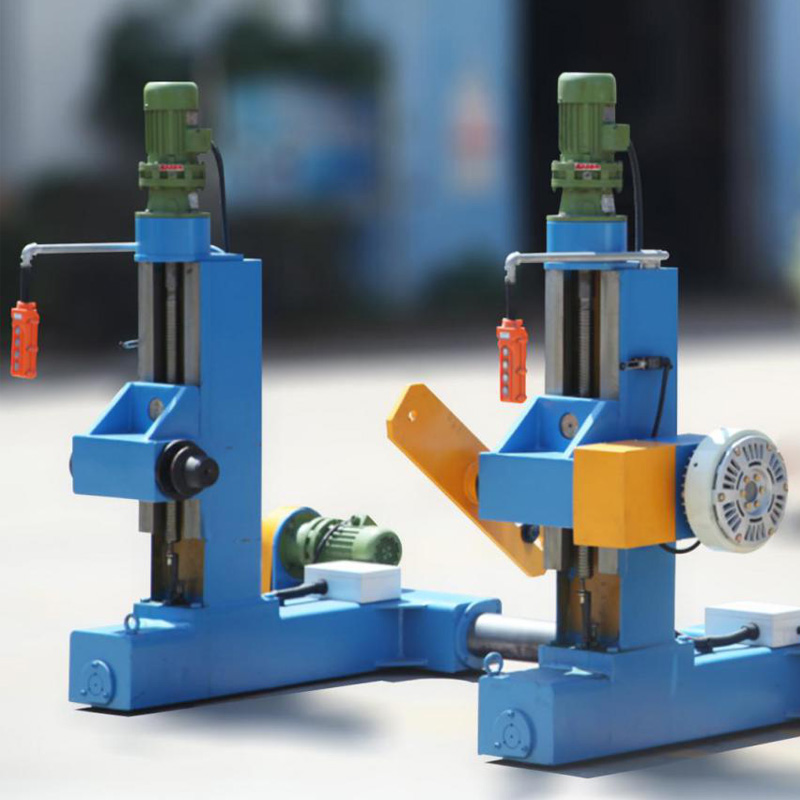

The power transformer is the key equipment in the power transmission system. The transformer oil tank carries the entire body and is filled with transformer oil. Therefore, the weld strength and sealing are two important indicators of the transformer.

The welding process of the transformer oil tank is complicated, the quality requirements are high, and the production cycle is long. If manual welding is used, it will be difficult to maintain the stability and consistency of welding work for a long time due to the influence of workers' psychological conditions, physiological conditions, and surrounding environment, which will cause problems such as low welding efficiency and unstable quality, and the welding surface is relatively poor.

This requires a robotic welding machine suitable for transformer oil tanks to meet the full-automatic welding requirements of transformer oil tanks, improve welding consistency and reliability, improve production efficiency, and reduce oil leakage from transformer oil tanks.

The robotic welding machine provided by LINT TOP are mostly used for welding transformer oil tanks, and can also be used for welding construction machinery, auto parts, agricultural machinery and other products.

2. Features

The robotic welding machine provided by LINT TOP has the following characteristics:

(1) A number of exclusive patents, the cost performance exceeds similar products.

(2) Joint gear gap adjustment, fine control, fast dynamic response.

(3) Hollow joint support structure, stronger rigidity and better flexibility.

(4) Noise reduction structure, soft running sound.

3. Technical Parameters

|

Model |

LT1400 |

|

Payload |

6kg |

|

Max. working radius |

1392mm |

|

Axis number |

6 |

|

Body weight |

165kg |

|

Position repeat accuracy |

±0.08mm |

|

Working temperature |

0~45℃ |

|

Protective grade |

IP40 |

|

Power capacity |

3.24kVA |

|

Note: In addition to the model in the table, it can also be customized according to customer needs. |

|

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for China Buy Wire Granulator Machine Factories - Robotic Welding Machine – LINT TOP , The product will supply to all over the world, such as: London, Manila, South Korea, Please feel cost-free to send us your specifications and we'll respond to you asap. We've got a professional engineering team to serve for the every single detailed needs. Free samples may be sent for you personally to know far more facts. So that you can meet your desires, please really feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.