China Buy Vertical Wire Drawing Machine Manufacturers - RBD Machine with Individual Drivers – LINT TOP

Product Details

China Buy Vertical Wire Drawing Machine Manufacturers - RBD Machine with Individual Drivers – LINT TOP Detail:

1. Introduction

In wire and cable products, traditional conductors are mainly copper and aluminum wires, but aluminum alloy cables have gradually gained widespread application in recent years. As the first process in the manufacture of cable products, the drawing of the conductor plays a vital role and is closely related to the quality of the product. Due to its large hardness, the use of traditional sliding gear-driven wire drawing machines can easily cause wire surface damage and drawing drum wear, which will affect the surface quality of aluminum wire and reduce the life of the drawing drum.The non-sliding drawing machine provided by our company, each drawing drum is driven by the separate motor independently. During the drawing process, there is almost no sliding between the wires and the drums, which greatly reduces the surface damage of the wires and effectively guarantees the quality of the wires. This is particularly suitable for drawing aluminum alloy wires.

In addition, copper and aluminum drawing machines with individual motors can also be provided according to customer needs to meet customers' drawing requirements for different products. At the same time, we can also provide two types of single head and double head drawing machines for customers to choose, in order to meet customer demand for production capacity.

2. Equipment Features

2.1 There is basically no sliding friction between the wires and the drum surface when drawing, which can extend the service life of the dies and the drums.

2.2 Compared with the traditional gear drawing machine, it can save about 20% of electricity

2.3 When drawing large-size wires, you can turn off the unnecessary motors, this can save up to 20% of energy consumption.

2.4 The elongation of each dies can be adjusted flexibly according to production requirement.

2.5 The drums are arranged in line with quick dies change. When the wire specifications are changed, it is only necessary to replace the finished die and reduce the drawing dies, which is convenient for threading the dies and change the wire specifications.

3. Main Technical Parameters

|

Model |

LT-D9M |

LT-D11M |

LT-D13M |

|||

|

Applicable materials |

Cu/Al/Al alloy |

Cu/Al/Al alloy |

Cu/Al/Al alloy |

|||

|

No. of wires |

1 |

2 |

1 |

2 |

1 |

2 |

|

No. of dies |

Max.9 |

Max.11 |

Max.13 |

|||

|

Inlet diameter (mm) |

Cu: 8.0 |

Cu: 8.0 |

Cu: 8.0 |

|||

|

Al/Al alloy: 9.5 |

Al/Al alloy: 9.5 |

Al/Al alloy: 9.5 |

||||

|

Outlet diameter (mm) |

Cu:2.20~3.60 |

Cu:1.60~3.60 |

Cu:1.20~3.60 |

|||

|

Al/Al alloy: 2.60~4.70 |

Al/Al alloy: 1.80~4.70 |

Al/Al alloy: 1.50~4.70 |

||||

|

Drawing speed (m/min) |

Max.1200 |

Max.1500 |

Max.1500 |

|||

4. Comparison of Energy Consumption

Comparison of energy consumption between our drawing machine with individual motors and a gear type drawing machine for drawing 2.6mm copper wire, as follows:

|

Type |

Motor |

Driving method |

Reduction rate |

Maximum output (Reference) |

Summary |

|

Individual motors |

AC+Siemens, high-efficiency servo motor frequency conversion |

Front 6-axis reducer + motor drive, rear toothed belt pulley + motor drive |

10%~30% Adjustable; slight slip, low noise |

2.6mm*20h (2 pcs) 120T,110 degree/T |

High efficiency and energy saving, low noise, large production capacity and less labor |

|

Gear type |

Host DC motor + lead DC motor |

2 DC motors 500kW + 90kW |

23%~25%, fixed reduction |

2.6mm*2 180 degree/T |

Large noise, high energy consumption, dies and drums are easy to wear and cannot change the reduction rate |

Example: Take the peak electricity as 1.11 yuan / degree and the valley electricity as 0.3 yuan / degree: the average electricity cost is: (1.11 + 0.3) / 2 = 0.7 yuan / degree.

The production capacity of 2.6mm * 2 copper wires is calculated at 20 hours per day,it can produce 120T copper wires per day. The gear drawing machine consumes 180 degrees / T of power, and the drawing machine with individual motors consumes 110 degrees / T. The difference is 70 degrees / T.

70 degrees / T*120 T=8400 degrees (per day)*0.7 yuan (average electricity bills)=5,880 yuan (electricity bills)

5880 yuan (One-day electricity ills difference)*30 days *12 months=2,110,000 yuan (Electricity saved in one year).

The above data is for reference only!

The drawing machine with individual motors from us can not only draw copper wires and aluminum wires, but also more suitable for aluminum alloy wires. It is the first choice for drawing aluminum alloy wires.

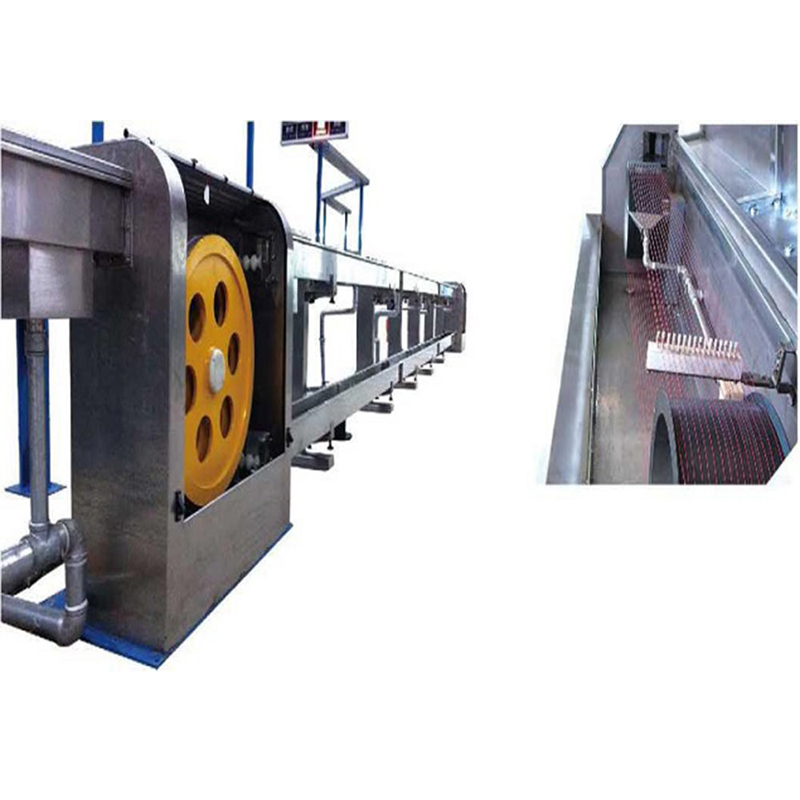

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for China Buy Vertical Wire Drawing Machine Manufacturers - RBD Machine with Individual Drivers – LINT TOP , The product will supply to all over the world, such as: Ecuador, Mombasa, America, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.