China Buy Uv Laser Machine Manufacturers - Aluminum Centrifugal Filter – LINT TOP

Product Details

China Buy Uv Laser Machine Manufacturers - Aluminum Centrifugal Filter – LINT TOP Detail:

Aluminum powder will be generated during drawing because of the friction between aluminum wire and dies while the wire or cable conductor drawing process and will exist in drawing emulsion. The powder will increase viscosity of drawing emulsion and raise the temperature of drawing emulsion, thus reducing the quality of the drawing emulsion. The drawing emulsion containing more aluminum powder also easily causes the aluminum wire to break and the surface is not smooth during the drawing process, which not only causes the surface of the wire to lose its brightness, but also affects the performance of the wire.

Removing aluminum powder from drawing emulsion will reduce emulsion viscosity, so the aluminum will go through the dies with good lubricating. It’s very necessary to remove aluminum powder from drawing emulsion.

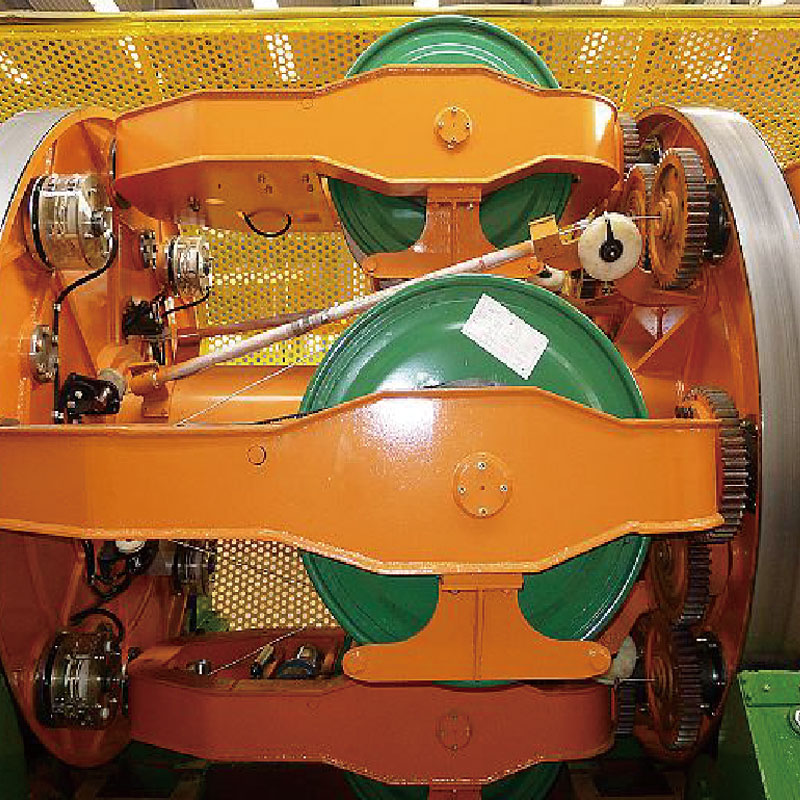

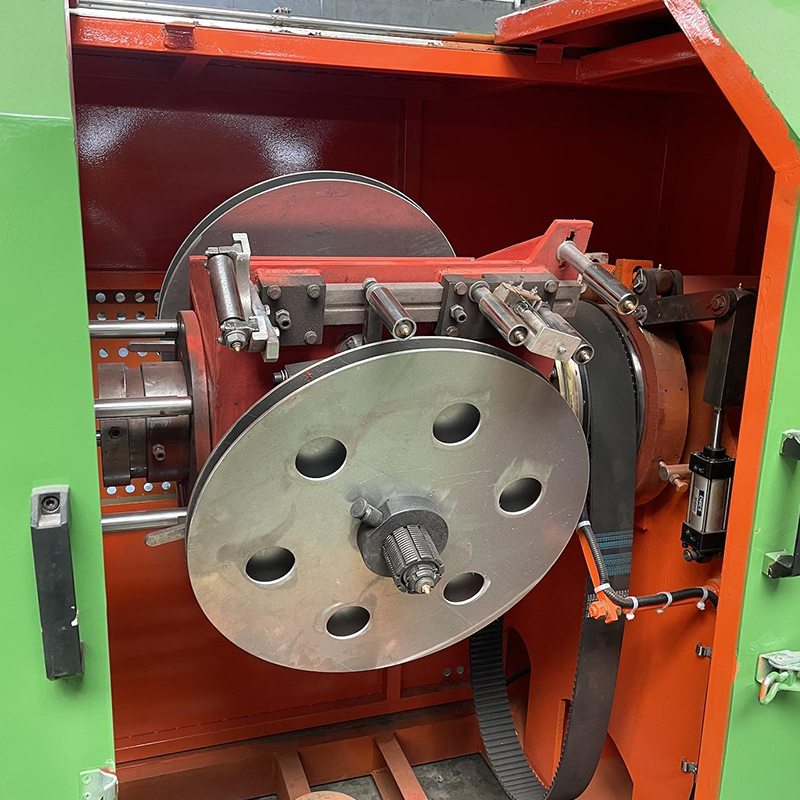

The aluminum centrifuge filter from us is a special equipment for separating the drawing emulsion and aluminum powder in the drawing process. The centrifugal force of the liquid is used to disperse the impurities to the surroundings, so that the drawing emulsion is separated from the aluminum powder. The rotating speed of the separator is as high as several thousand revolutions per minute. Under the action of strong centrifugal force, all the residual impurities, aluminum powder, sludge, carbon black, colloid, mixed metal particles and so on are separated.

The treated emulsion can keep the content of aluminum powder less than 0.3% and the viscosity of the drawing emulsion in a reasonable range.

We provide two types of aluminum centrifugal filter: Manual centrifugal filter and full-automatic centrifugal filter.

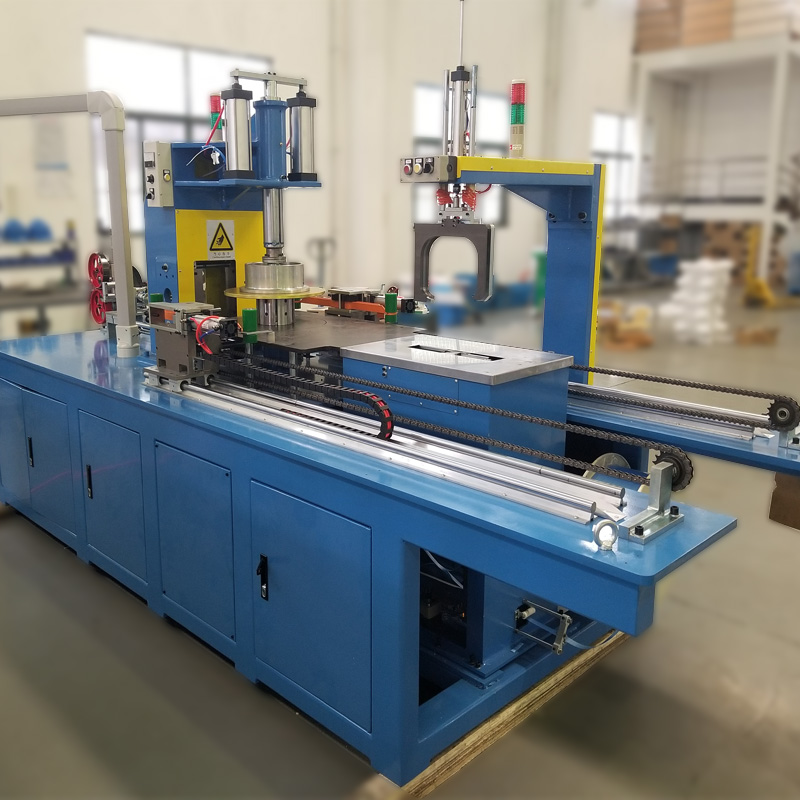

1. Manual Centrifugal Filter

The manual centrifugal filter only relies on the pressure of the oil pump to provide the rotational driving force, and the centrifugal force generated is more than 1,800 times the gravity, which can directly drive the solid pollutants such as aluminum powder, impurities, particles and the like from the drawing emulsion.

The whole machine adopts adjustable working pressure, which is composed of centrifuge, oil pump, electrical, instrument and other parts.

The solid frame structure forms an integrated machine, and the universal four-wheel brake can ensure the safe operation of the equipment within the range of 0.5m2.

The working noise of this equipment can be as low as 80dB and the filtering accuracy can reach 10μm. According to the aluminum powder content concentration of the customer's drawing emulsion pool, the amount of aluminum powder separated per hour ranges from 0.5kg to 8kg, the degree of drying varies from 90% to 98%, and the emulsion content is less than 0.5%.

The whole machine has the function of overpressure, overload shutdown protection. When the operating pressure of the equipment is too high, it will automatically depressurize and shutdown. The operation only needs to click the switch, which makes it more convenient to use.

Main features:

(1) Double spray structure, floating rotor body, self-lubricating structure, no abrasion and wearing parts;

(2) Large dirty hold ability, small footprint, space saving, flexible movement and convenient maintenance;

(3) Only the pressure generated by the oil pump is required to provide driving force, low energy consumption, maintenance-free, no need to replace any parts, rapid processing, etc.

2. Full-automatic Centrifugal Filter

The full-automatic centrifuge is a top-end equipment for aluminum powder processing of aluminum wire drawing machine. It has stronger centrifugal force to separate aluminum powder from the drawing emulsion.

The emulsion to be processed is sprayed into the rotary tank of the centrifugal filter from the bottom of the rotary body through an auxiliary pump. Under the high-speed rotation of the emulsion in the cylinder, the aluminum powder is separated from the emulsion and adsorbed on the rotor barrel wall. The separated emulsion overflows from the top of the rotating body, flows back to the drawing emulsion through the direction of the preset separation tank pool.

After the rotor cylinder has condensed certain aluminum powder and impurities, the equipment automatically reduces the rotor speed, automatically shuts off the emulsion and waits until the rotating body is completely stopped. The automatic slag removal function is activated to open the slag discharge opening, and the built-in scraper of the drive motor is activated to clean the aluminum powder. The scraper will rotate in order, rotating the coulter repeatedly and scraping out the aluminum powder cake. Under the action of gravity, aluminum powder falls from the slag discharge port into a collecting barrel below the equipment.

This machine adopts intermittent working mode. When the aluminum powder is separated, the emulsion pump works and the cleaning stops. During the cleaning operation, the aluminum powder and the emulsion pump stop working.

Main features:

(1) The whole series adopts Siemens and Schneider CPU, frequency converter, touch screen, motor and other main components, and the whole machine runs stably, reliably and efficiently;

(2) Solid one-piece frame welding and assembly process, more solid durability, ensure the whole machine working life longer;

(3) The design is novel, the added structure is reasonable, the system runs stably and reliably, high intelligence, the automatic slag removing and oil discharging is realized, the manpower and material resources are greatly saved;

(4) The automatic operation only needs to click the start and stop buttons to complete the operation. The system is equipped with manual / automatic switch, which can be set at any time in 24 hours, and 100% humanized operation;

No consumables, no maintenance, meet strict environmental requirements.

3. Main Technical Parameters

|

Type |

Manual centrifugal filter |

Full-automatic centrifugal filter |

||

|

LT-100AHF |

LT-125AHF |

LT-83T |

LT-135T |

|

|

Flow (L/h) |

5200 |

6000 |

4980 |

8100 |

|

Rotating speed (rpm) |

4500 |

4200 |

3300 |

3200 |

|

Dirty hold ability (cm3) |

5800 |

6500 |

/ |

/ |

|

Total power (kW) |

3 |

4 |

5.7 |

7.7 |

|

Inlet / outlet pipe diameter (mm) |

32/60 |

38/60 |

25/80 |

32/80 |

4. Features

1. Simple structure, easy maintenance and long service life;

2. Improving the quality of the drawing emulsion, greatly extend the life of the drawing emulsion, and save the consumption of the drawing emulsion;

3. No wearing parts and consumables, spare parts need to be replaced; high separation accuracy and wide separation range, it can greatly reduce the maintenance cost;

4. It will not block the filter material that cause flow reduction, pressure difference rise, filter element replacement and other maintenance;

5. No complicated processes such as heating, stirring, standing, cleaning the aluminum drawing machine emulsion tank, etc;

6. Wide range of processing emulsion, separation accuracy up to 10 μm, impurity removal rate> 98.7%.

The aluminum centrifugal filter guarantee those aspects: Improving work efficiency, improving drawing production process, improving drawing product qualification rate and save energy.

Product detail pictures:

Related Product Guide:

With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and development, we will build a prosperous future together with your esteemed company for China Buy Uv Laser Machine Manufacturers - Aluminum Centrifugal Filter – LINT TOP , The product will supply to all over the world, such as: Serbia, Pretoria, Palestine, Our company follows laws and international practice. We promise to be responsible for friends, customers and all partners. We would like to establish a long-term relationship and friendship with every customer from all over the world on the basis of mutual benefits. We warmly welcome all old and new customers to visit our company to negotiate business.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.