China Buy Strander Machine Suppliers - Metal Sheathing Line Argon Arc Welding, Molding and Corrugating – LINT TOP

Product Details

China Buy Strander Machine Suppliers - Metal Sheathing Line Argon Arc Welding, Molding and Corrugating – LINT TOP Detail:

To meet the needs of economic development, the power supply system is developing towards higher and higher voltage levels. In the power supply system, ultra-high-voltage power cables play a role in power transmission. These types of cables generally require a metal sheath structure to meet the performance requirements of the cable itself and the requirements of the environment.

At present, metal sheath of ultra-high voltage power cables is generally protected by inert gas (helium or argon), after the aluminum tape (stainless steel tape) is finely cut, the longitudinal seam is formed by a special mold and then the longitudinal seam is welded. Finally, it is produced by stretching, sizing and crimping. LT-HG200 argon arc welding, molding and corrugating production line provided by our company is a special equipment for manufacturing high-performance ultra-high voltage power cable metal sheath.

The technical difficulty is welding process, but we have rich experience in this field. By drawing on the technical characteristics of the European welding production line, taking advantage of the shortcomings, continuous technological innovation, the reliability, stability and convenient operation of the equipment welding have become the domestic leading level, which can be comparable to European equipment.

1. Features

1. Easy to operate. The welding torch can meet the arbitrary adjustment of the three axis directions of X, Y, and Z, with the welding gun rapid turning device, and the welding gun automatic tracking system to ensure that the welding pin is always directly above the welding seam.

2. Stable operation. Specially designed forming tool and multi-channel horn die gradual forming to ensure stable welding.

3. Humanized design. The production line can roll ring patterns and spiral patterns, patterns of rolling can be concentric or eccentric. The depth and pitch of corrugating can be adjusted online.

2. Main Technical Parameters

|

Welding Tube Outside Dia. (mm) |

Ф60-Ф200 |

|

Welding Metal's Thickness (mm) |

Aluminum:0.8-4.0 Copper: 0.3-1.5 Stainless steel: 0.3-1.0 |

|

Welding Speed |

0-4.6m/min, continuous adjustable |

|

Corrugation Type |

Helical or annular |

|

Corrugation Thread Pitch (mm) |

10-50 |

|

Corrugation Depth (mm) |

1.0-8.0 |

|

Protect Gas |

Argon, Helium (For aluminum) |

The equipment adopts specially designed forming tools and crimping machines, so that it has excellent cable manufacturing stability and is the first choice for the manufacture of ultra-high voltage power cable metal sheaths.

3. Production Process

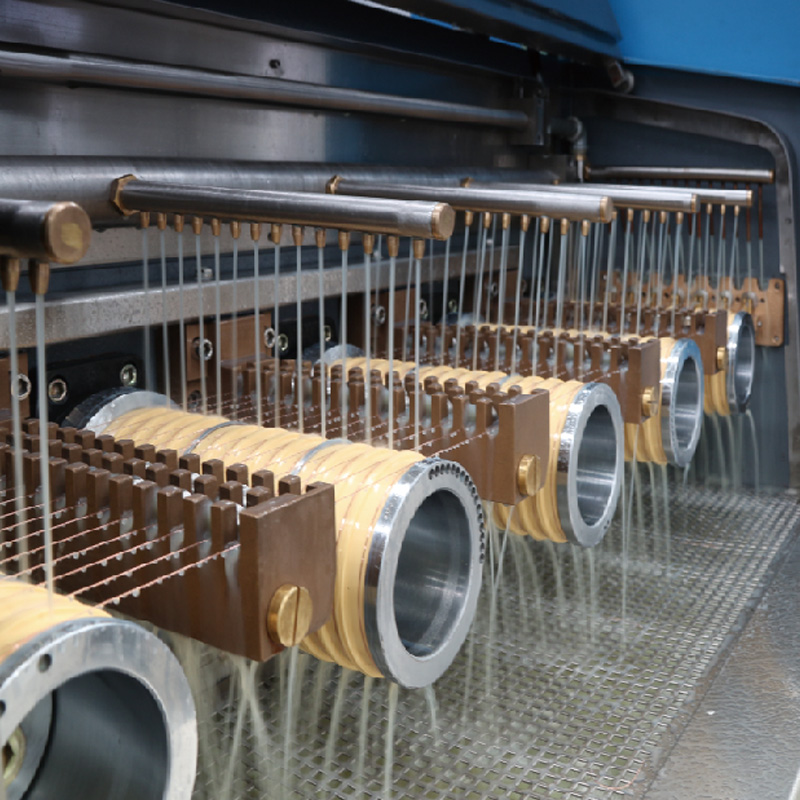

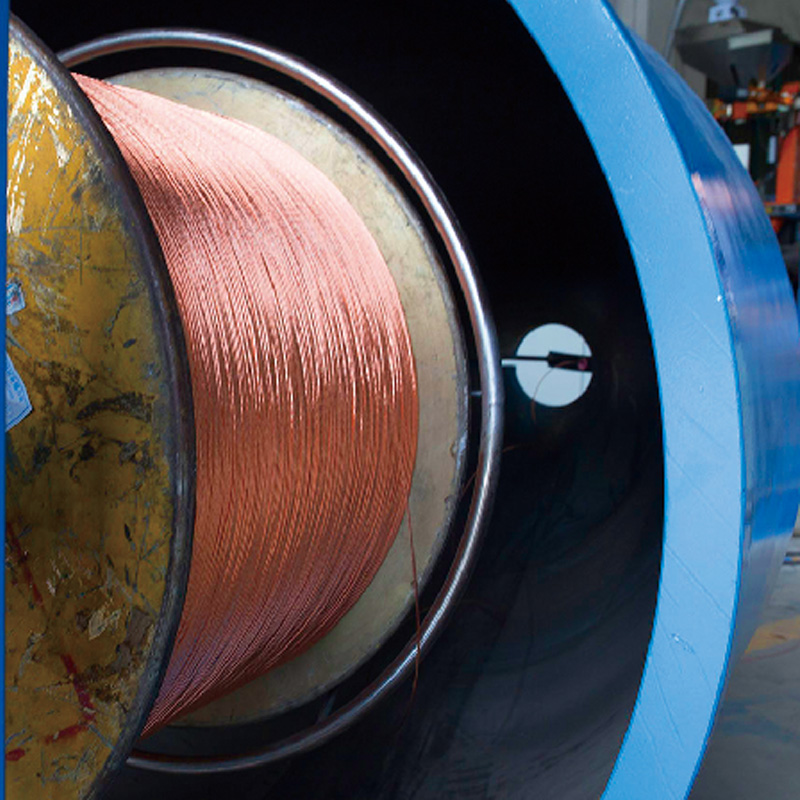

Cable pay off→Core kickstand→Metal tape pay-off→Strip edge trimmer→Scrap take-up→ Precision longitudinal wrapping→Argon arc longitudinal butt welding→Arc monitoring→Stretch sizing→Caterpillar capstan→Corrugating machine→Take-up

4. Corrugating Effect

In addition, the equipment also can weld and corrugate copper tapes according to different product needs.

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for China Buy Strander Machine Suppliers - Metal Sheathing Line Argon Arc Welding, Molding and Corrugating – LINT TOP , The product will supply to all over the world, such as: Iran, Curacao, Namibia, We are always creating new technology to streamline the production, and provide goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.