China Buy Rod Breakdown Machine Factories - Drawing, Annealer, Pre-heating Insulation Tandem Extrusion Production Line – LINT TOP

Product Details

China Buy Rod Breakdown Machine Factories - Drawing, Annealer, Pre-heating Insulation Tandem Extrusion Production Line – LINT TOP Detail:

Nowadays, the world has already entered the information society. LAN, the basic unit of high-speed information network, its transmission rate is getting faster with the development of society.

The data cable is one of the most important transmission media of the LAN, and the development of the LAN is also driving the rapid growth of the data cable. In the future for a long time, data cables will be used widely .

In order to meet the high-speed information transmission requirements of today's social networks, data cables have evolved from the lower transmission rates like Cat.3, Cat.5e, and Cat.6 to higher transmission rates of Cat.6A, Cat.7, and Cat. 7A and even the highest category Cat.8.

With the development of communication networks, Cat.6A and higher categories of data cables have become the mainstream products of network wiring systems. In order to achieve better transmission performance, such data cables no longer use traditional solid insulation, but must use foam insulation type. In order to ensure that the insulated wire core reaches a highly precise geometric size and the best quality. At present, the extrusion of Cat.6A and above categories adopts a drawing skin-foam-skin insulation tandem extrusion production line.

Insulation extrusion is the most critical production process for data cables. The quality of the insulation is directly related to the performance indicators of the entire data cable product. Our company has many years of experience in research and development and manufacturing of data cable production equipment. Our drawing-skin foam skin insulation tandem extrusion production line has many core technologies, which are suitable for Cat.6A, Cat.7, Cat.7A, Cat.8 production of foam insulation. The test performance of the finished cable products can meet the requirements of ISO 11801, IEC 61156, ANSI / TIA 568 and other standards.

1. Features

1) Adopting drawing, continues annealing, pre-heating integrated machine to make copper conductor and insulation adhere well;

2) The main extruder adopts the most advanced gas injection foaming screw in the world, with stable discharge and uniform foaming;

3) The inner and outer skin extruder adopts frequency conversion and vector control to make the inner and outer skin thickness uniform and consistent;

4) Adopting German high-precision nitrogen pressurized gas injection system and precision gas needle to produce fine and even bubbles;

5) Adopting automatic dual take-up and bobbin change, which can realize automatic bobbin change without stopping, which greatly improves production efficiency;

6) Full line industrial computer control, online control of copper wire diameter, insulation outer diameter, water capacitance, concentricity, foaming degree, etc.

The drawing, annealer, pre-heating insulation tandem extrusion production line provided by our company has more than 80% market share in China, and is also exported to various countries in the world. Choosing us means not only chose the world-class data cable foam insulation production line, but also chose first-class technical support and after-sales service. This production line has extremely high commissioning difficulty, but we have a professional technical team that can assist customers to successfully complete the installation and commissioning of the production line, provide customers with professional technical training, and enable customers to truly master foam production technology. At the same time, according to the size of the wire produced by the customer, the design of the wire drawing dies and the foam extrusion dies can be free for the customer.

2. Main Technical Parameters

|

Max.inlet dia. of copper wire (mm) |

2.6 |

|

Outlet dia. of copper wire (mm) |

0.40~0.65 |

|

Max. completed outer diameter of insulation |

3.0 |

|

Applicable insulation materials |

LDPE、MDPE、HDPE |

|

Applicable insulation type |

Skin-foam-skin |

|

Insulation concentricity (%) |

≥95 |

|

The highest degree of foaming (%) |

70 |

|

Production speed (m/min) |

Solid PE: max.1200 Skin-foam-skin PE: max.1000 |

|

Operating direction |

From left to right / right to left |

3. Production Effect

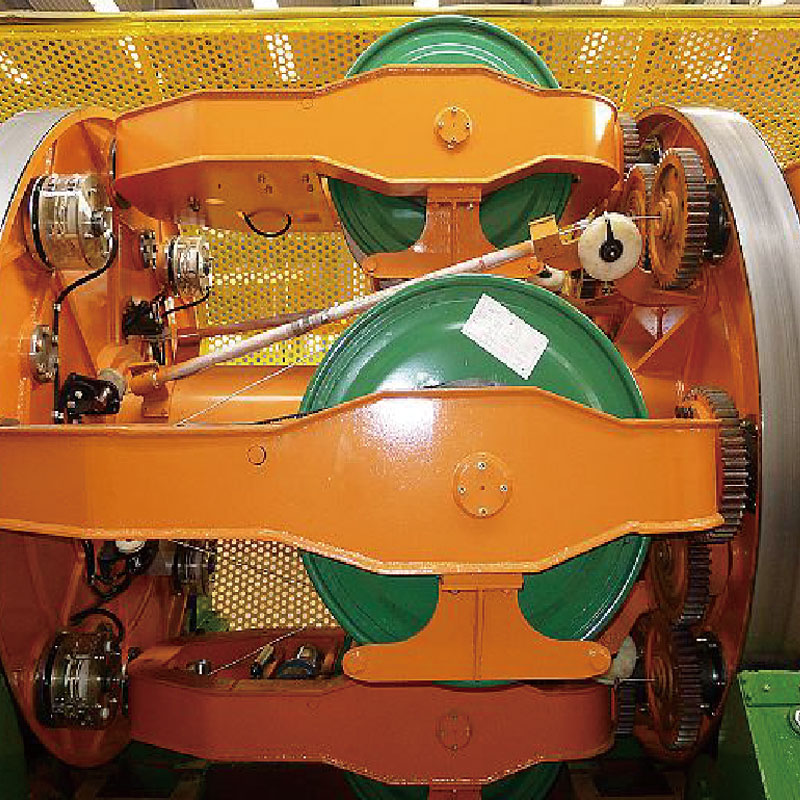

Product detail pictures:

Related Product Guide:

Our products are broadly identified and trustworthy by people and may meet continually modifying financial and social requires of China Buy Rod Breakdown Machine Factories - Drawing, Annealer, Pre-heating Insulation Tandem Extrusion Production Line – LINT TOP , The product will supply to all over the world, such as: Seattle, India, The Swiss, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.