China Buy Line Wire Factories - Bunching Machine – LINT TOP

Product Details

China Buy Line Wire Factories - Bunching Machine – LINT TOP Detail:

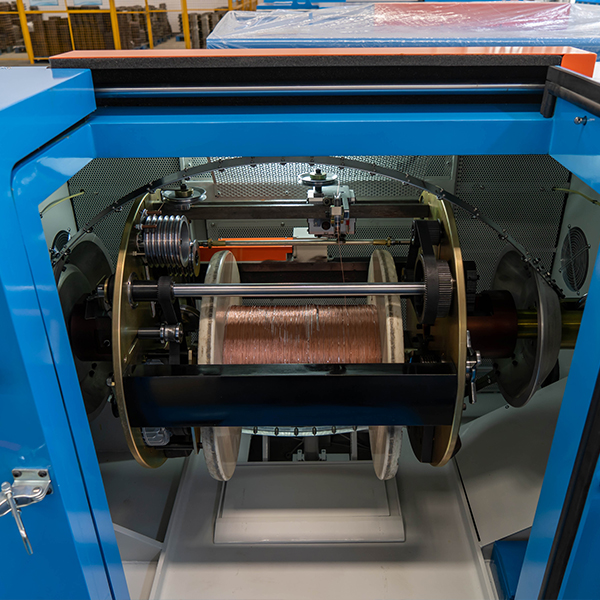

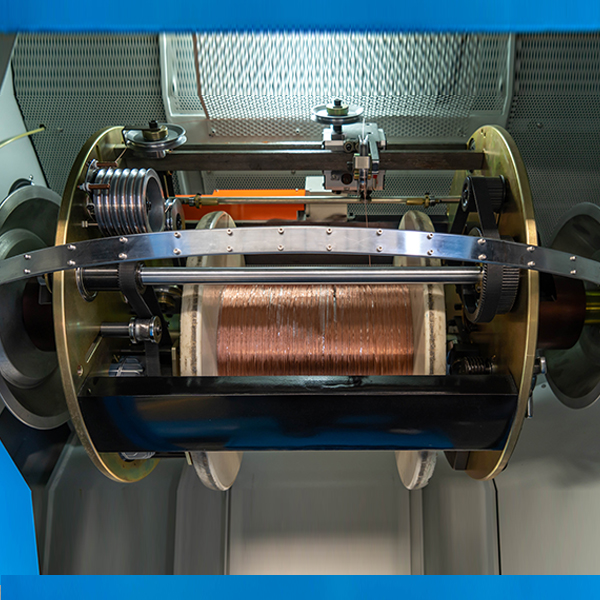

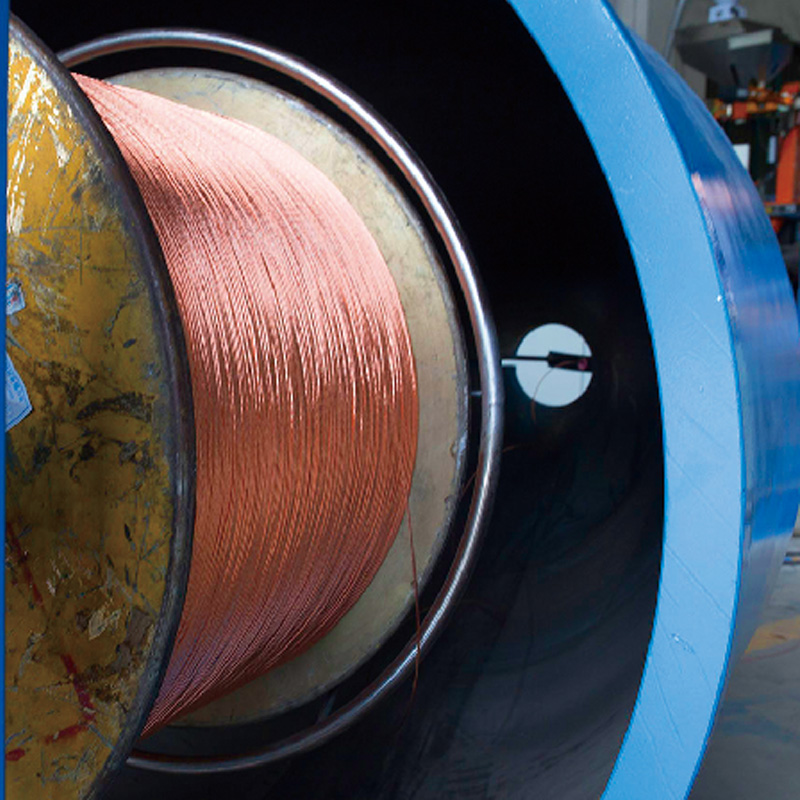

In the production of wire and cable, multiple strands of wire need to be stranded before the insulation can be extruded. The stranding of multi-stranded wires can be carried out on stranding machines or bundling machines. When the diameter of a single wire is very fine, the number of strands is high and the wire is particularly soft, the traditional stranding equipment cannot meet the requirements and a bunching machine can only be used. Multiple single wire pay-off reels are placed in layers and rows on a fixed support and together they enter the main machine via a dividing plate. The rotation of the rotating body twists the single wires and completes the stranding of the wire.

We can offer a wide range of bunching machines for bare copper, tinned copper, silver-plated copper, copper-clad aluminium, special alloy and insulated core wires. Not only can they be used for stranding multi-stranded wires, but they can also replace (1+6) tube stranding and (1+6) frame stranding for regular stranding. Compared to the tube and frame stranding machines, the production capacity of the bunching machine is (2 to 4) times higher.

1. Equipment Features

(1) The user-friendly design makes operation easier and more convenient. Advanced PLC, touch screen and frequency control technology are used. The running program, instructions and machine self-test are all controlled by PLC, which is technologically advanced and reliable in operation.

(2) The professional program design ensures the reliability of the system. The imported magnetic powder clutch is used to control the tension and has a unique automatic tracking and adjusting design, so that the tension of the whole reel is even and consistent, thus the quality of the stranded wire is greatly improved.

(3) The special stranding bow material and unique design ensure that the quality of the stranded wire is not affected during high speed operation. With the latest wire crossing system, the wire enters the bow belt directly from the spindle guide wheel. The bow belt has a unique semi-circular groove design, which protects the wire from wind resistance during high speed operation, so that the stranded wire is no longer scratched or skipped.

(4) The electromagnetic brake is used to brake, and the brake is automatically applied when the wire is broken internally or externally, or when there are various faults.

(5) The whole machine are used synchronous belt drive, the machine without oil, stranded wire from oil pollution.

2. Main Technical Parameters

|

Model |

LT500 |

LT560 |

LT630 |

LT800 |

LT1000 |

|

Max. rotation speed (rpm) |

3000 |

3000 |

2000 |

1200 |

1000 |

|

Inlet wire diameter (mm) |

0.08~0.52 |

0.08~0.52 |

0.10~0.68 |

0.30~1.70 |

0.68~2.13 |

|

Stranded outer diameter(mm) |

≤2.2 |

≤2.2 |

≤3.3 |

≤6.5 |

≤9.0 |

|

Stranded cross-sectional area(mm²) |

0.035~2.5 |

0.035~2.5 |

0.18~6.0 |

2.5~16 |

4~25 |

|

Stranding direction |

S or Z (Optional) |

||||

The double twist buncher machines we offer can meet the requirements of different wire sizes. It has high speed, high efficiency, light weight, small footprint, low noise level and high quality.

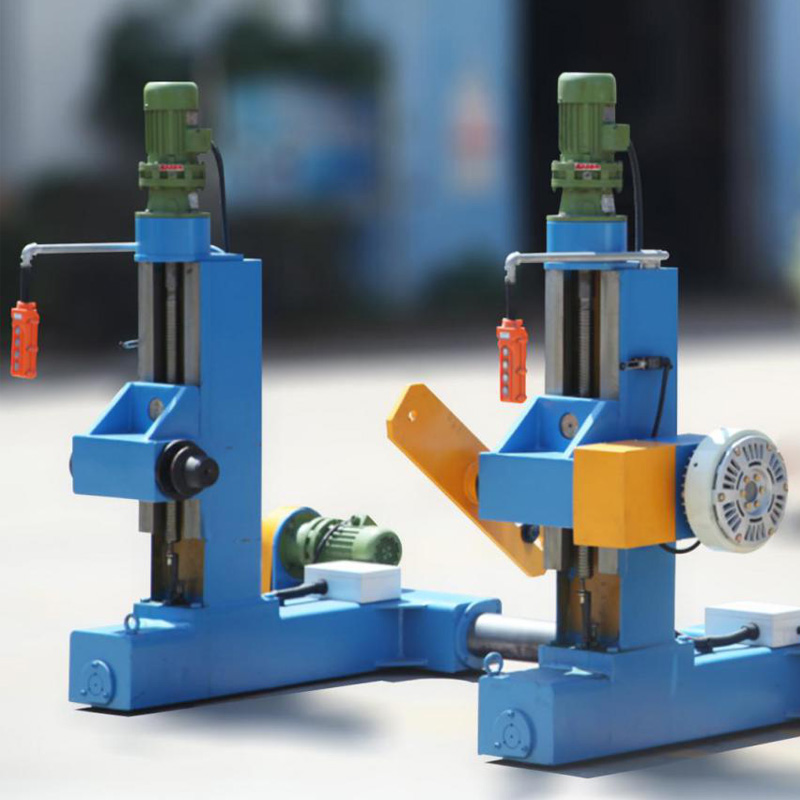

Product detail pictures:

Related Product Guide:

Our business sticks for the basic principle of "Quality could be the life with the firm, and track record will be the soul of it" for China Buy Line Wire Factories - Bunching Machine – LINT TOP , The product will supply to all over the world, such as: Austria, Argentina, Pretoria, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we will continue to develop, to provide the high-quality products and services, and promote lasting cooperation with our customers, common development and create a better future.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.