China Buy Extrusion Manufacturing Process Exporters - Trolley Type Heat and Aging Furnace / Aluminum Alloy Wires Annealing Furnace – LINT TOP

Product Details

China Buy Extrusion Manufacturing Process Exporters - Trolley Type Heat and Aging Furnace / Aluminum Alloy Wires Annealing Furnace – LINT TOP Detail:

In order to improve the mechanical properties of aluminum alloy wires after drawing, quenching heat treatment is generally required. But the strength and hardness of aluminum alloy wires do not immediately increase after quenching, in order to improve the strength and hardness of aluminum alloy wire, aging treatment after quenching is required.

The aging of aluminum alloy wire can occur at normal temperature, which is called “natural aging”. However, due to the low temperature, the natural aging progresses slowly, which seriously affects the production and processing of the next process. The heating method can promote the mobility of metal atoms and accelerate the restoration of the aluminum alloy to a stable state. The process at artificial high temperature is called "artificial aging". "Manual aging" can restore the performance of the aluminum alloy wire after quenching in a short time, which greatly improves the production efficiency. This is generally called an aging furnace.

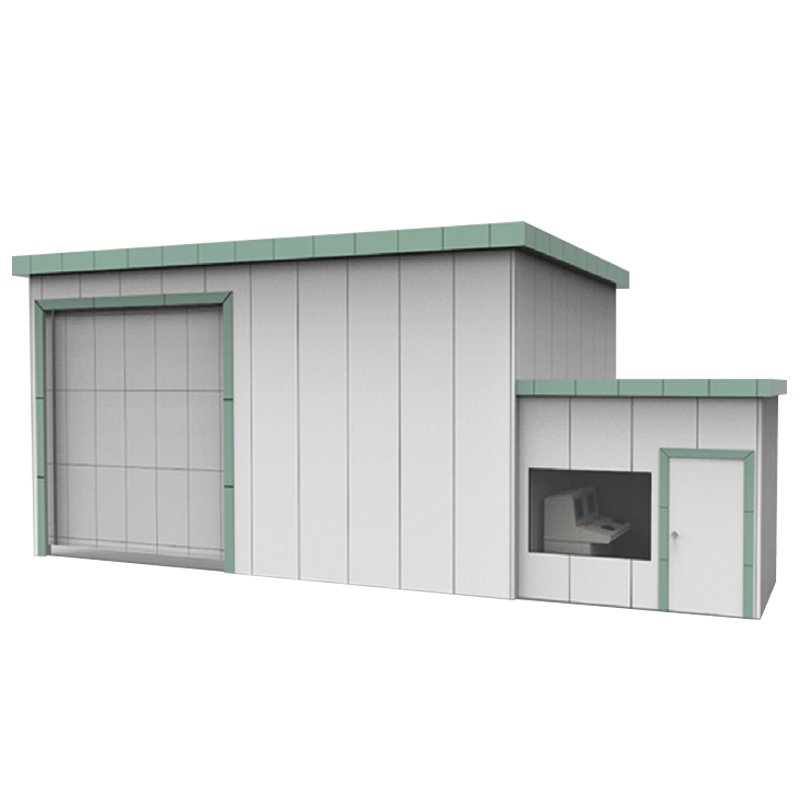

The trolley-type aluminum alloy aging furnace from us can meet the aging treatment of a large number of aluminum alloy wires, and is the best equipment for aging treatment of aluminum alloy wires for wires and cables.

1. Equipment Features

1. Processed parts with uniform hardness and less deformation;

2. Easy operation and maintenance;

3. Reliable performance, low failure rate;

4. Electric control system with high precision;

5. Small space occupation;

6. Low price and energy saving.

2. Main Technical Parameters

|

Bobbin Nos. |

32,40,64,80,96,etc (can be customized) |

|

Rated temperature (℃) |

150~300(temperature adjustable) |

|

Furnace uniformity(℃) |

±5 |

|

Bobbin size (mm) |

φ630*500/pcs |

|

Surface temperature rise of furnace shell (℃) |

≤30 |

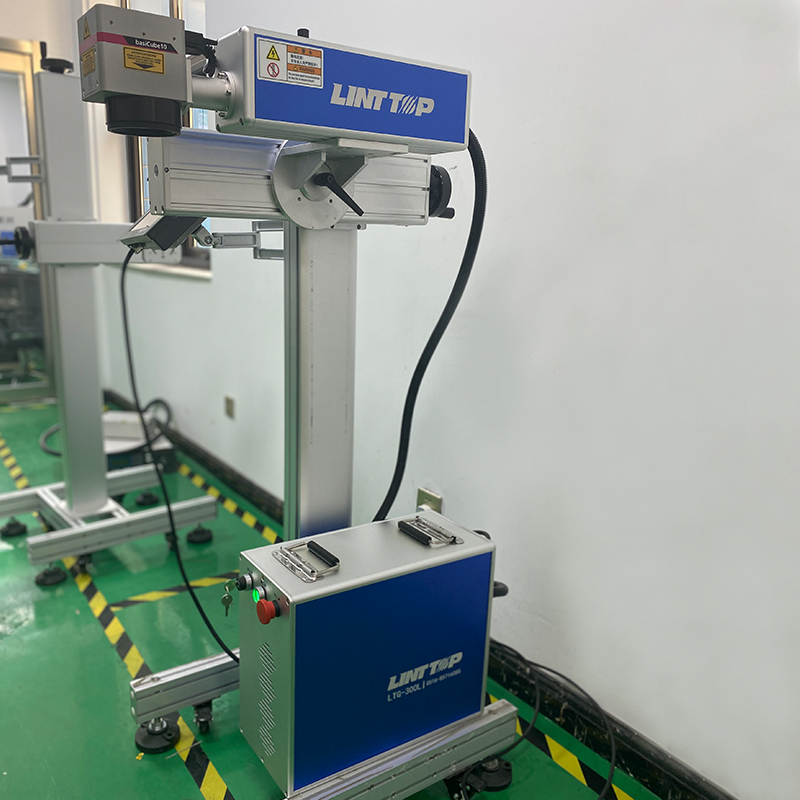

Product detail pictures:

Related Product Guide:

As a way to ideal meet up with client's desires, all of our operations are strictly performed in line with our motto "High Top quality, Competitive Cost, Fast Service" for China Buy Extrusion Manufacturing Process Exporters - Trolley Type Heat and Aging Furnace / Aluminum Alloy Wires Annealing Furnace – LINT TOP , The product will supply to all over the world, such as: Angola, Turin, Hongkong, The credibility is the priority, and the service is the vitality. We promise we have the ability to provide excellent quality and reasonable price products for customers. With us, your safety is guaranteed.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.