China Buy Building Wire Exporters - Full-automatic Rewinding Machine – LINT TOP

Product Details

China Buy Building Wire Exporters - Full-automatic Rewinding Machine – LINT TOP Detail:

1. Introduction

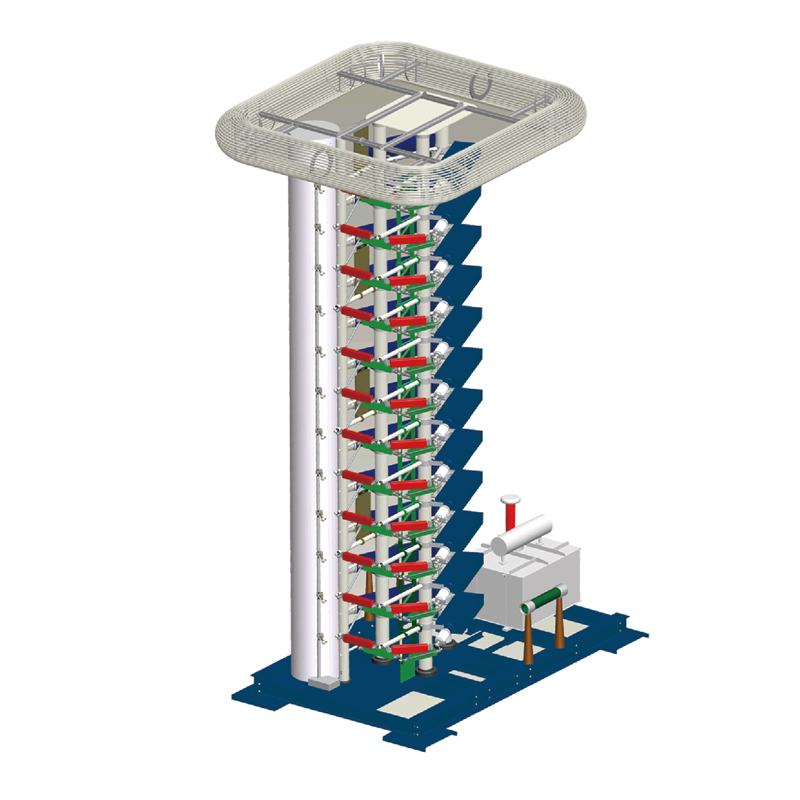

The rewinding machine is an auxiliary equipment of the braiding machine, which is used to rewind the metal wires onto the braiding bobbin orderly and evenly.

The traditional rewinding machine is semi-automatic type, by which the bobbin loading, unloading, clamping, and wire cutting all need to be operated manually, and the number of rewinding heads is generally only up to 3. The operators need to do frequent bobbin loading and unloading work during the machine is running, which greatly increase labor cost and low working efficiency.

In order to solve the problems existing in the traditional rewinding machines, our company has developed a new type of full-automatic rewinding machine with very simple structure and adopts a 2.2kW variable frequency motor. The bobbin loading, clamping, doubling, end clamping, wire cutting, and bobbin unloading are all completed automatically by the program control set by the PLC, which can replace manual operation, realize automatic production and reduce cost and increase efficiency.

The rewinding machine adopts a four-axis parallel structure, which makes multiple bobbins can run at high speed at the same time to improve the efficiency of rewinding production. The traversing system uses a servo motor to drive a high-precision ball screw and tracks the change of the frequency conversion motor speed automatically through the feedback signal of the encoder to ensure the constant pitch traversing. With the function of wire breaking and fault alarm, the alarm lamp flashes and stops automatically when any end or many ends of wires breaking, and the rest of rewinding heads can continue to work. The form of the pay-off rack can be passive type, motorized type, static plate, etc. according to the wire diameter.

2. Features

The automatic rewinding machine we provide has the following characteristics:

(1)Automatic stop when the payoff wire broken or no payoff, the bobbins have the automatic braking device;

(2)It will automatically stop when the metal wires are rewinded to the set numbers which ensures the same capacity of each bobbin;

(3)Frequency control is used to control the rewinding speed on the touch screen steplessly;

(4) Adopting the precise traversing device, the traversing is neat and the tension of the wire doubling is stable, which improves the quality of the wire arrangement.

(5) Electronic meter counter is used to ensure the high precision.

3. Main Technical Parameters

The main technical parameters of automatic rewinding machine are shown in the following table:

|

Rewinding material |

Copper wires, aluminum magnesium alloy wires, etc. |

|

Number of rewinding heads |

1~4 |

|

Bobbin size(mm) |

φ75×φ22×70 |

|

Max. Bobbin speed(rpm) |

3000(Stepless) |

|

Number of wires per rewinding head (wire) |

2~10 |

|

Single wire diameter(mm) |

0.05~0.25 |

|

Rewinding pitch(mm) |

0.1~3.0 |

|

Bobbin stocking(pc) |

92(According to customers’ requirements ) |

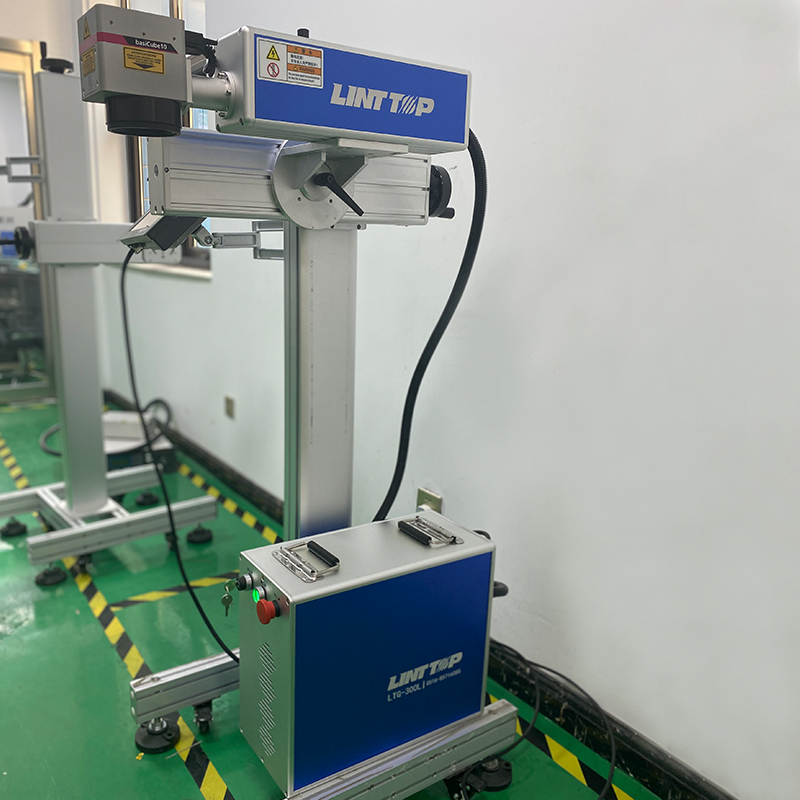

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for China Buy Building Wire Exporters - Full-automatic Rewinding Machine – LINT TOP , The product will supply to all over the world, such as: Venezuela, Sao Paulo, Madras, "Make the women more attractive "is our sales philosophy. "Being customers' trusted and preferred brand supplier" is the goal of our company. We are strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.