Aluminum/Aluminum Alloy Rod Continuous Casting and Rolling Line(CCR)

Product Details

1. Product Introduction

The aluminum/aluminum alloy rod continuous casting and rolling line adopts the continuous casting and rolling process to produce 1-series, 3-series, 5-series (with magnesium content not exceeding 1%) and 8-series (8030, 8176) aluminum/ aluminum alloy rod. It is mainly used in wire and cable, magnet wire and other aluminum/ aluminum alloy rod manufacturing industries.

The production line fully realizes electromechanical integration. The whole production line adopts the combination of DC speed regulation and AC frequency conversion speed regulation, which has strong production synchronization, high efficiency and low energy consumption. Full production line adopts PLC automatic control, industrial computer to collect and store data and monitor, color touch screen display and operation, with fault alarm and automatic shutdown protection functions.

2. Production Process

Aluminum ingot/ molten aluminum → batching → refining → slag removal → stand still → online refining → filting → continuous casting → power straightening → traction → cut → casting blank transition support device → induction heating device ( the heating furnace includes a closed cooling device, which is an option) → rough rolling → finish rolling → aluminum/ aluminum alloy rod.

The horizontal continuous casting machine ensures the smooth casting of molten aluminum and greatly reduces the production slag. The induction heater effectively guarantees the process temperature requirement for the cast billet to be rolled, and has the function of heating and adjusting the billet.

The continuous rolling mill has the function of active feeding and rod stacking parking. The continuous quenching device has the function of online quenching. The outlet of the take-up conduit is equipped with a water blowing device to remove the surface moisture of aluminum/ aluminum alloy rods. At the same time, an active traction device is installed to ensure the smooth export of aluminum/ aluminum alloy rods.

The arc guide tube adopts the roller guide structure to reduce the surface abrasion of the aluminum/ aluminum alloy rod. The way of rod winding is the centrifugal shaking head type. On the one hand, the aluminum/ aluminum alloy rod can be pre-deformed before entering the take-up frame. On the other hand, if the rod is broken during the rolling process, the rod tail can be automatically placed in the wire take-up frame. When changing bobbins, the rods are not disturbed, so as to ensure that the continuous double-bobbin coiler device is used for winding up.

3. Technical Parameters

|

Crystal wheel diameter |

Φ2200mm |

|

Crystal wheel section form |

"H" type (cooling water device adopts cylinder propulsion form) |

|

production capacity |

(6-7.5)t/h |

|

Ingot section |

≈3400mm2 |

|

coiled rod diameter |

Φ2200mm |

|

Finish weight |

≤2.85t/bundle |

|

PLC controller |

ethernet(TCP/IP) |

|

I/ O Spare |

20% |

|

Continuous uptime |

≥8h |

|

Emulsion temperature in continuous operation |

≤60℃ |

|

Equipment running noise |

≤95dB |

|

Aluminum(alloy ) rod diameter |

Standard diameter±3% |

|

Out of roundness |

≤0.3mm |

|

Appearance quality of aluminum(alloy) rod |

The surface of aluminum(alloy) rods should be clean, and there should be no defects such as folded edges, wrong rounds, cracks, inclusions, kinks, and other defects that affect the use |

For more information on different configurations and capacities, please click: Aluminum (Alloy) Rod Production Line.

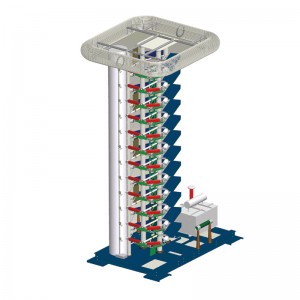

Main Componets

This production line is mainly composed of continuous casting machine, power straightening machine, front tractor, rolling shearing machine, casting blank transition support device, feeder, roughing mill, finishing mill, cooling and quenching device, coiler, take up trolley and basket, electrical control system, continuous rolling mill lubrication integration system, continuous rolling mill emulsion circulation filtration purification and cooling device, etc.

(1) Continuous casting machine

The continuous casting machine consists of upper and lower pouring pots, aluminum liquid temperature measuring device, flow regulating device, crystallization wheel and rotating device, pressing wheel device, steel tape tensioning device, idler wheel, steel tape air blowing and water wiping device, ingot picking device and oiling device, ingot approach bridge, stainless steel water cooling device, water pressure display, electromagnetic flowmeter flow display and gas system, etc. All components are installed on an integral box, and the continuous casting machine is an integral casting machine, which is convenient and quick to install and adjust.

In order to ensure dense and uniform crystallization of the ingot, the crystallization wheel is cooled by spraying water from all sides. The cooling water is managed in zones, and each section of the pipeline is equipped with a manual water control regulating valve and a flow meter display instrument, and has a pressure display. In order to facilitate cooling water adjustment and maintenance, internal cooling, external cooling, and side cooling are installed on a pneumatically propelled platform, which can be easily pushed out from the crystallization wheel. The cooling system of the casting machine is closed, and the water vapor generated when cooling the crystallization wheel is sucked out by the induced draft fan to the outside, so as to avoid air holes and air bubbles caused by the aluminum liquid suction.

Horizontal casting is adopted to reduce turbulent air suction, and the molten aluminum flows smoothly from the bottom pouring pot to the crystallization wheel during casting, ensuring that the aluminum liquid does not produce turbulent flow and air suction, thereby improving the quality of the billet. In order to ensure that the tension and compression force can be adjusted, the tension and compression of the steel tape are pneumatic tensioning and pneumatic compression. The tension wheel and the pressure wheel have a deflection adjustment mechanism for correcting and adjusting the steel tape.

The molten aluminum enters the upper pouring pot through the launder. There is an overflow port at the rear end of the upper pouring pot, through which too much molten aluminum flows into the emergency bag, so that the aluminum liquid level of the upper pouring pot remains relatively stable, and it also plays a role of safety protection. The upper pouring pot is installed on a support. When it is necessary to stop casting immediately, the pouring pot is manually turned over, and the remaining liquid of the pouring pot and the launder flows into the emergency bag. There is a discharge port at the bottom of the other end of the upper pouring pot. The aluminum liquid is put into the lower pouring pot through the discharge port. The aluminum liquid is temporarily stored in the lower pouring pot, and then flows into the crystallization wheel groove through the sprue.

(2) Continuous rolling machine

The continuous rolling machine is composed of motor, coupling, feeder, roughing mill, finishing mill, planetary reducer, transmission gearbox, base and so on.

The qualified billet produced by continuous casting is sent to the continuous rolling machine through the feeding device, firstly passes through four two-roll stands for rough rolling, and then enters ten three-roll Y-shaped stands for finish rolling, and the rolled aluminum/ aluminum alloy rod send out the take-up. Among them, 1#, 2#, 3#, and 4# frames are driven by single motor, and 5# to 14# frames are driven by centralized transmission.

The gearbox gears of the finishing mill are all made of 20CrMnTi material and ground, the stand bearings are made of NSK bearings from Japan, the rolls of the finishing mill are made of H13 material, and the lubricating and cooling water pipes of the rolling mill stand are made of hoses and contain quick connectors.

The rolling mill is equipped with a fume collection system to send the flue gas outside the plant. The rolling mill is equipped with a protective cover, which is in the form of a hydraulic flip cover to prevent emulsion splashing and smoke collection, and is equipped with a visible cover plate for daily inspection.

(3) Rod take-up system

The rod take-up system is mainly composed of an operating platform, a guide tube, an arc-shaped raceway, a rod swing device, and a double-basket take up trolley, etc.

The rolled aluminum/ aluminum alloy rod is sent into the conduit device, and then enters the rod swing device. When the speed of the rod swing transmission device is fast, the coiling diameter is small; when the speed is slow, the coiling diameter is large, and the speed can be adjusted steplessly.

When the aluminum/ aluminum alloy rod falls into the rod take-up basket, the rod take-up system can realize free landing centrifugal type and automatic plum blossom type. The coiling diameter of the aluminum/ aluminum alloy rod is automatically controlled by PLC without manual adjustment.

There is a driving device under the trolley, which is driven to change the basket. If the aluminum/ aluminum alloy rod needs to be cooled and quenched, the water valve can be opened, then the cooling water can spray on the surface of the aluminum/ aluminum alloy rod for quenching treatment, and the cooling water is sprayed into the water bag of the take-up pipe by adjusting the water volume switch. The inside of the tube plays a role of cooling and lubricating the aluminum/ aluminum alloy rod, and the amount of water can be adjusted according to the requirements to control the soft and hard strength of the aluminum/ aluminum alloy rod.

(4) Electrical control system

Continuous casting machine, front traction and feeder adopt Siemens frequency converter for speed regulation, and DC motor of continuous rolling machine adopts DC speed regulation and synchronous control.

The PLC uses Siemens S7-1200 for programming, and the touch screen uses Siemens KTP1200 color touch screen (man-machine interface) for operation. The touch screen of the man-machine interface and PLC perform two-way data exchange, and the monitoring and control of the system is realized through PLC program control. It can accurately and reliably command and coordinate the work of the entire system, and various operating parameters are centrally monitored and displayed. Real-time monitoring and data collection and storage are carried out on the equipment through the industrial computer, and the hourly output, cumulative output, coiled weight and process parameters in process management can be displayed online. The expandability of the equipment is strong, facilitate the collection of production data. The centralized control device of the equipment must reserve an Ethernet interface for communication with the upper computer.

When a single machine is running, the speed of the casting machine, front tractor, rolling shear, rolling machine, and rod coiling can be individually adjusted through the console. During linkage operation, the speed of the entire line is based on the speed of the casting machine, the front traction machine, rolling machine, coiler automatically track the speed of the casting machine. The linkage speed is provided with speed fine-tuning for the front tractor and rolling mill.

The process flow of the whole production line is visually displayed with full animation, which can conveniently issue operation instructions and check the operation status of the equipment. At the same time, the system will give an abnormal prompt to the current and motor speed, and the continuous rolling mill will automatically alarm and stop automatically when the rod is blocked and piled up.

The electric control cabinet part should be placed in a dedicated power distribution room, the main operating console should be placed in the control room, and only the pole winding machine operation auxiliary table and emergency switch should be placed on the production site.

Schneider products are used for buttons and indicator lights; Schneider products are used for control relays; Schneider products are used for low-voltage electrical appliances below 65A.

Technical Training

LINT TOP not only provides customers with excellent equipment, but more importantly, we can provide customers with professional and comprehensive equipment use and maintenance training for more than one month, so as to improve the ability of customers’ operators and maintenance personnel to master the equipment.

For the operators and maintenance personnel of the mechanical system, electrical system and hydraulic system, the customer needs to send qualified engineers to attend the meeting, including all casting personnel, maintenance personnel, electrical equipment maintenance personnel, automation management personnel for PLC support and maintenance.

For furnace operators, casting operators and rolling mill operators, the training content includes aluminum alloy formula, production process, operating points, etc., to ensure that on-site operators can master the equipment operation methods proficiently and produce qualified aluminum(alloy) rods.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.