2019 wholesale price Cable Metal Bobbin - Drawing Dies – LINT TOP

Product Details

2019 wholesale price Cable Metal Bobbin - Drawing Dies – LINT TOP Detail:

1. Introduction

Polycrystalline diamond is manufactured by forming a mass of diamond crystals and then applying a combination of heat and pressure. Through this process, the mass becomes a single unit with the diamond particles inter-grown to each other. The final product is extremely wear resistant, maintains tight hole tolerances, and provides good surface finish.

Carbide dies have been used in the wire industry for many years. They are used in various drawing applications where diamond dies are not economical or where hole tolerance is not as critical.They are used extensively in the steel industry as well as the nonferrous industry in applications such as bunching or stranding large diameter cables. These dies are available in a large range of nib and hole sizes.

2. Natural Diamond Dies

Key benefits of LINT TOP ND diamond wire dies:

Long die life due to its extreme hardness and resistance to scratching.

Can be used in high-heat processes because of its extreme thermal conductivity.

Easy setup, smooth drawing.

100% of all diamonds are checked for inclusions, cracks.

Non-conductive properties make this product a good choice when electrical conductive materials are an issue.

Diameter range and standard tolerance of natural diamond dies:

|

Size Range (mm) |

Standard Tolerance (mm) |

Roundness(mm) |

|

-0.020ˉ |

0.0007 |

0.00035 |

|

0.020-0.051ˉ |

0.0010 |

0.0005 |

|

0.051-0.102ˉ |

0.0010 |

0.0005 |

|

0.102-0.203ˉ |

0.0015 |

0.00075 |

|

0.203-0.508ˉ |

0.0020 |

0.0010 |

|

0.508-1.016ˉ |

0.003 |

0.0015 |

|

1.016-1.524ˉ |

0.0050 |

0.0025 |

|

1.524-1.981ˉ |

0.007 |

0.0035 |

|

>1.981 |

0.010 |

0.005 |

Typical reduction angle and bearing length:

|

Reduction of Area |

Lead/Zinc/ Silver/Gold |

Aluminum /Nickel/Copper |

Brass Bronze Stainless Steel |

High Carbon Steel |

Hot Tungsten |

|

8-12% |

16° |

12° |

11° |

10° |

10° |

|

12-16% |

18° |

14° |

13° |

12° |

12° |

|

16-25% |

22° |

18° |

16° |

15° |

12° |

|

25-35% |

24° |

22° |

19° |

18° |

14° |

|

Bearing length |

0.2-0.5d |

0.4-0.8d |

|||

Note: we also provide artificial diamond dies with competitive price.

3. Polycrystalline Diamond Dies

Key benefits of diamond wire dies:

Available for almost any type of wire drawing operation, from rod-size to fine-size.

Can be used for wet and dry drawing applications.

Predictable wire surface quality.

Contain randomly oriented diamond crystals, making certain that wire remains round; even with significant wear the wire remains round.

Blank dimensions are guaranteed, hence maximum recut dimensions can be predicted.

Diameter range and standard tolerance of natural diamond dies:

|

Size Range (mm) |

Standard Tolerance (mm) |

Roundness(mm) |

|

0.051-0.102ˉ |

0.0010 |

0.0005 |

|

0.102-0.203ˉ |

0.0015 |

0.00075 |

|

0.203-0.508ˉ |

0.0020 |

0.0010 |

|

0.508-1.016ˉ |

0.003 |

0.0015 |

|

1.016-1.524ˉ |

0.0050 |

0.0025 |

|

1.524-1.981ˉ |

0.007 |

0.0035 |

|

>1.981 |

0.010 |

0.005 |

Typical reduction angle and bearing length:

|

Reduction of Area |

Lead/Zinc/ Silver/Gold |

Aluminum /Nickel/Copper |

Brass Bronze Stainless Steel |

High Carbon Steel |

Hot Tungsten |

|

8-12% |

16° |

12° |

11° |

10° |

10° |

|

12-16% |

18° |

14° |

13° |

12° |

12° |

|

16-25% |

22° |

18° |

16° |

15° |

12° |

|

25-35% |

24° |

22° |

19° |

18° |

14° |

|

Bearing length |

0.2-0.5d |

0.4-0.8d |

|||

4. Tungsten Carbide Wire Drawing Dies

Key benefits of carbide dies:

Sizes are available up to 90 mm rod.

Cost effectively.

Even and round wear during usage.

Specifications of tungsten carbide nibs and dies.

|

Inches |

||||

|

Type |

(NIB) |

(CASING) |

||

|

Dia. |

Ht. |

Dia. |

Ht. |

|

|

R2 |

.325 |

.330 |

1 |

9/16 |

|

R3 |

.450 |

.380 |

1-1/2 |

3/4 |

|

R4 |

.500 |

.450 |

1-1/2 |

7/8 |

|

R5 |

.625 |

.600 |

1-1/2 |

7/8 |

|

R6 |

.710 |

.700 |

2 |

1-1/8 |

|

R7 |

.768 |

.768 |

3 |

1-3/8 |

|

R8 |

1.000 |

.820 |

3 |

1-3/4 |

|

R9 |

1.187 |

.820 |

3 |

1-3/4 |

|

R10 |

1.500 |

1.000 |

3 |

2 |

|

R11 |

1.8300 |

1.250 |

4 |

2-1/4 |

|

R12 |

2.185 |

1.375 |

4 |

2-3/8 |

|

R14 |

2.560 |

1.375 |

6 |

2-1/2 |

|

R15 |

3.000 |

1.375 |

6 |

2-1/2 |

|

R16 |

3.500 |

1.375 |

7 |

2-1/2 |

|

R17 |

4.000 |

1.500 |

7 |

2-1/2 |

|

R18 |

5.500 |

2.125 |

9 |

4-1/2 |

|

R19 |

6.500 |

2.125 |

11 |

4-1/2 |

|

Millimeters |

||||

|

Type |

NIB |

CASING |

||

|

Dia. |

Ht. |

Dia. |

Ht. |

|

|

B |

13 |

10 |

30 |

16 |

|

D |

16 |

14 |

32 |

20 |

|

G |

22 |

18 |

40 |

26 |

|

H |

30 |

21 |

66 |

35 |

|

K |

40 |

25 |

95 |

40 |

|

L |

50 |

28 |

95 |

48 |

|

M |

60 |

35 |

114 |

60 |

|

N |

75 |

35 |

114 |

70 |

|

O |

90 |

35 |

145 |

70 |

We also provide drawing dies that meet Japanese and German standard.

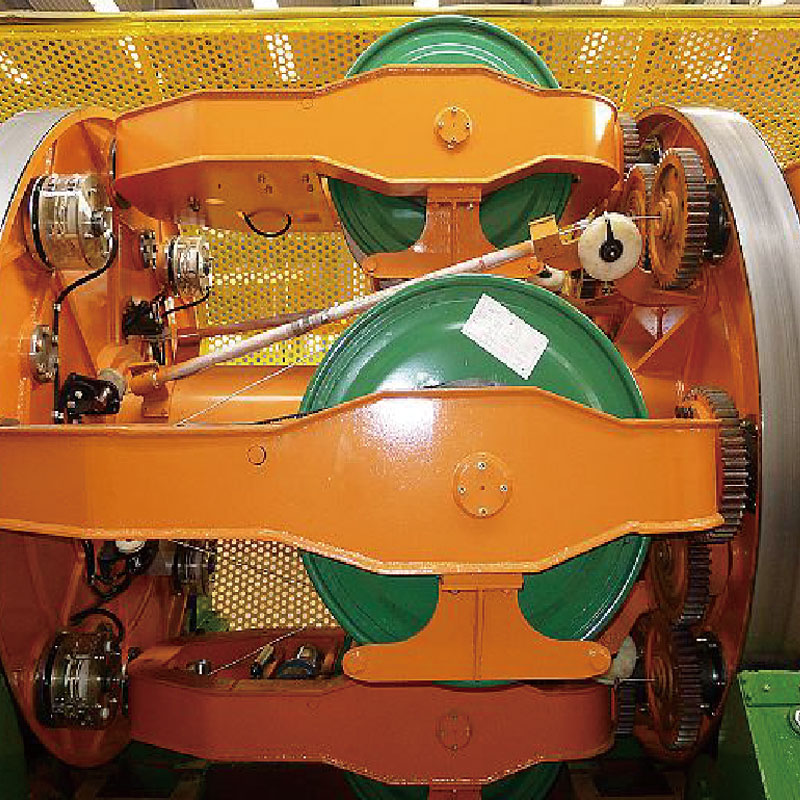

Product detail pictures:

Related Product Guide:

we are able to supply top quality items, aggressive price and greatest buyer assistance. Our destination is "You come here with difficulty and we offer you a smile to take away" for 2019 wholesale price Cable Metal Bobbin - Drawing Dies – LINT TOP , The product will supply to all over the world, such as: Brasilia, Turkey, Bahrain, So far our merchandise have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have now 13years experienced sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to provide our customers with high quality items and excellent service.

FAQ

Q: Can I visit your factory?

A: All the customers from both home and abroad are warmly welcomed to visit our company and factory.

Q: Do you supply the installation and commissioning?

A: Yes, we do as followings:

-As soon as customer informed us the machines are put in the right place, we will send both mechanical and electrical engineer for machine start up.

-No-load testing: After machine installed completely, we make no-load testing first.

-With-load testing: Usually we will can produce 3 different wires to make load testing.

-Acceptance report: After the buyer confirms that machine can reach all specification under contract, the acceptance report will be signed for our record that machine will be in guarantee period.

Q: What information should I offer to get a detailed quotation from you?

A: For single machine: Usually we need to know inlet wire size, outlet wire size to be produced, productivity, pay off and take up size to choose the right machine.

For new cable plant or new cable production line, we need to know the datasheet of cables to be produced, the productivity, the standards to be followed, etc to design all machines needed.

Q: Can you supply the auxiliary equipment along with the machines?

A: Yes, definitely.

We has supplied heat exchanger, copper/aluminum powder filter machine, cooling tower, chiller, air compressor, drawing dies, pointing machine, cold welders, bobbins etc. with our machines.

Q: Could you do the design for the whole plant?

A: Yes, this is our advantage.

With the data sheet of cable to be produced, the standard your cables should follows, the productivity you expected. Our engineer on production technology and machinery will make design of production machines, test equipment, accessories like bobbins, dies, rewinding lines and materials needed.

Q: How can I know the status of my order?

A: We have our OA system on tracking the production.

For any of your request we can send photos and videos of your order, also we can use FACETIME to let you know the production.

Q: How do you work on the inspection before delivery?

A: We will make dynamic balance testing, levelness testing, noise testing, etc. during production.

After production finished, usually we make no-load running of each machine before delivery. Customers are welcomed to attend the inspection.

Q: What exhibitions will you attend, can we meet in the fair?

A: Dusseldorf International Wire and Cable Fair;

Wire South America Fair;

International Wire and Cable Fair in Shanghai;

International Istanbul Wire Fair, etc.

wire Southeast Asia Fair, etc.